“Langbo Machinery customer service is one of the best encountered in the business. Always fast and effective act.”

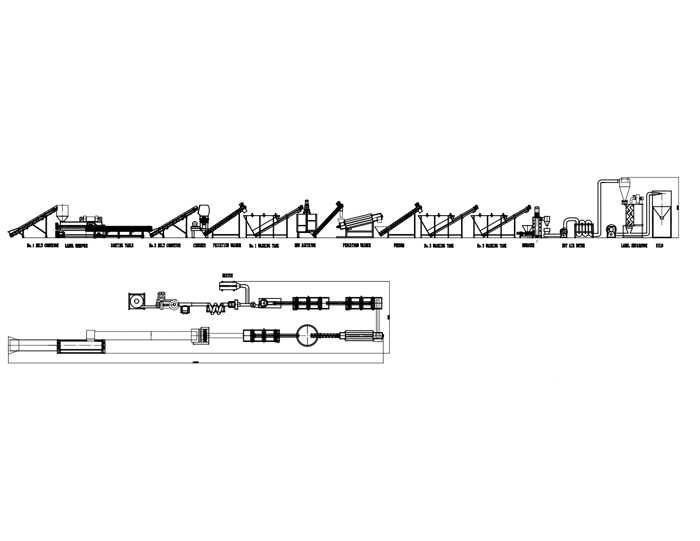

PET Bottle Recycling line

Plastic bottle crushing and recycling line

PET Bottle washing

PET bottle washing line working in Romania

Highlights

High automation grad

Demand oriented solution

Module structure for recycling line

Operator oriented control system

Few labors demanded

Tailored Solution

01.

Tailored Solution

For the best result of cleaning effect, the solution of washing line should be tailored. The reason is that the status of to be cleaned material and the requirement on final product is different. For certain demand we prepare tailored solution for our customer. So, if you have interest on washing solution, please feel free to contact us and get your tailored solution.

02.

Easy operation of Control cabinet

In the picture man can see, that each line part of the washing line can be monitored on the cabinet. The power on or off, the water temperature and the working status of motor or air blower can be seen clearly. It is easy to understand and operate.

03.

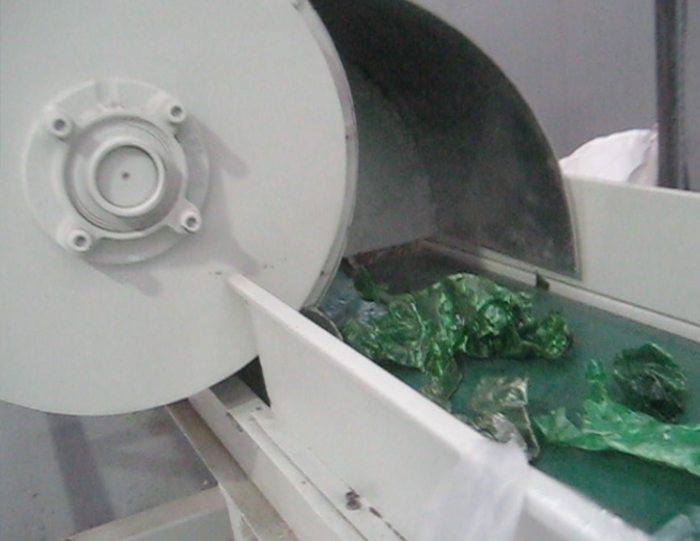

Label remover

For PET bottle washing the label remover is already a necessary part. It removes the the label which not made by PET.

04.

Comparison of Raw material and final product

Through the washing line the waste pet bottle will be crushed and cleaned as flakes. These flakes will be processed and recycled for pellets even pet bottles again.