Romania

PVC Granulating Line

PE Pipe Extrusion Line, LB-

PVC Profile Extrusion Line

Langbo Machinery is our friendly partner. We have cooperated for several times. They always provide the best quality and reasonable price.

Highlights

Automatic Coordination between Dosing and Haul-off

Few labor operation

Easy training and maintenance

Tailored Solution

01.

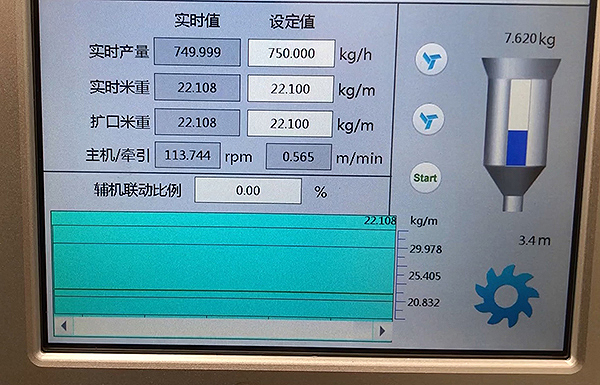

Gravimetric Dosing System

Gravimetric dosing system is widely used in the pipe extrusion, where the quality of pipe highly demanded such as wall thickness. With gravimetric dosing system the screw and haul-off will cooperated work to ensure a constant wall thickness. The computer in gravimetric dosing system monitors the working condition of extruder and control the haul-off speed.

02.

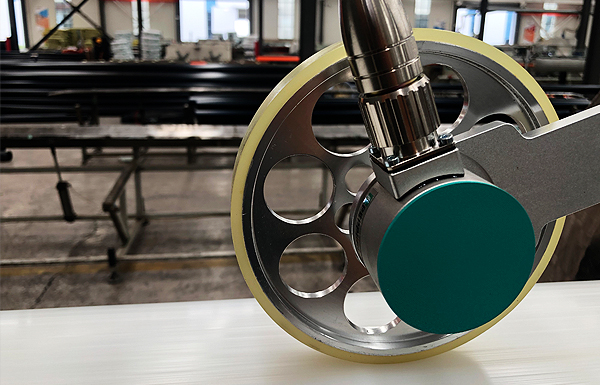

Tailored Combination of extruders

Co-Extrusion is widely used in production of large diameter pipe or the extrusion line with wide scope of pipe diameter. Based on discussion with customer, our engineer finds the pipe diameters, which mostly used in daily production. With this background a extruder combination plan will be proposed and confirmed with customer. This combination should provide enough extrusion volume and ensure each extruder running in the most efficiency speed range.

03.

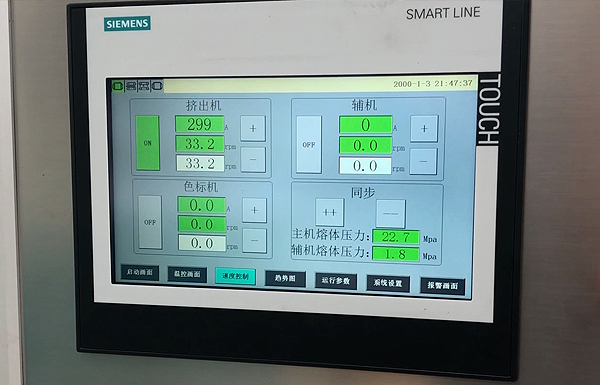

Easy control and operation

Touch screen helps operators easy to set every kind of production parameter. As production starts or pipe size changes, the operation on touch screen and control panel on vacuum tank will be easy and comfort, because the layout and function of control pages and bottoms is designed based on operation logic.

04.

High precise sensor

For high quality product and process stable production an on-time monitoring of production parameter is necessary. In our machines high precise sensors monitor the production conditions such as melt pressure, extrusion speed, pipe length and so on. All the date around production can be monitored on touch screen.