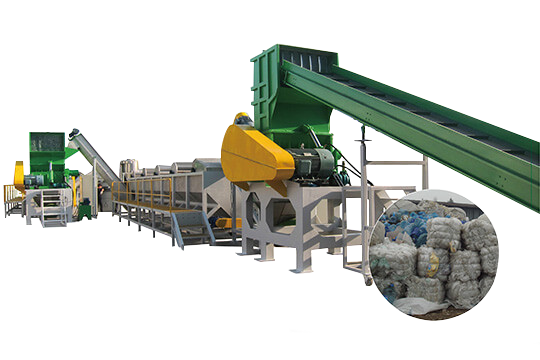

For a better cleaning effect, the PET bottle will be crushed into small particles. Small flakes will easier be cleaned with further steps. With different target material, the geometry and layout of crusher knife are different. The same is, that we use high quality alloyed material for knife to ensure a long and reliable working status.

High Efficiency conveying and robust structure. Friction between screws plays a role in film cleaning.

In the Floating washer the film scraps will be cleaned. Here the cold water mixed with ingredient like salt or alcohol separate the scraps and clean the material for next step

With friction hot water with chemical solution the sticky attached particle will be cleaned. Based on the application of film, the method will be applied in the washibg line.

After cleaning the scraps will be dried. The drying methods will be selected based on requirement and position. Scraps can be dried by warm wind or squeezing.