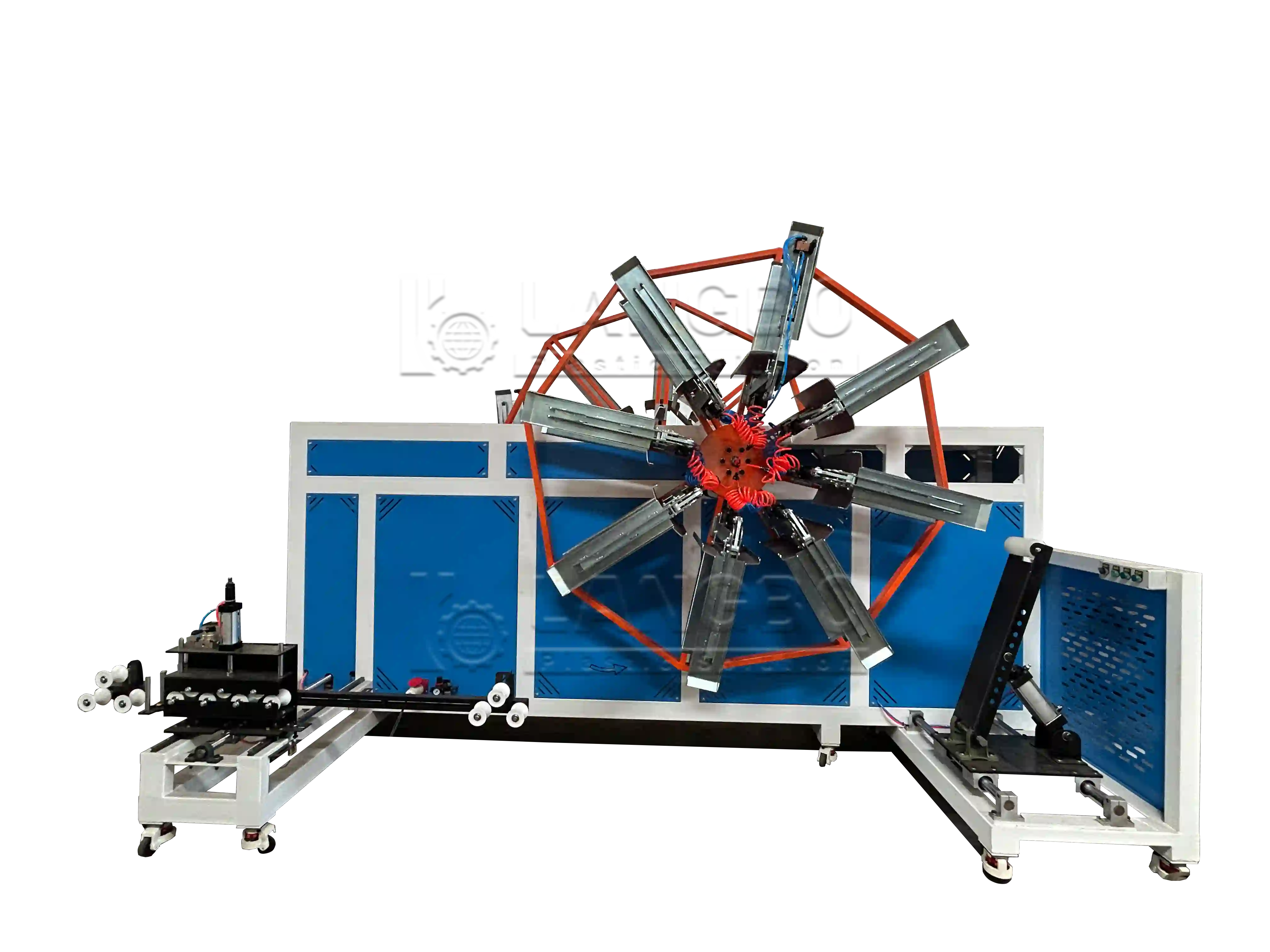

Suitabel for pipe 16-63mm

Torque motor for low speed and constant winding force

Standard design for disk size is for 100m length in a roll of the max pipe diameter

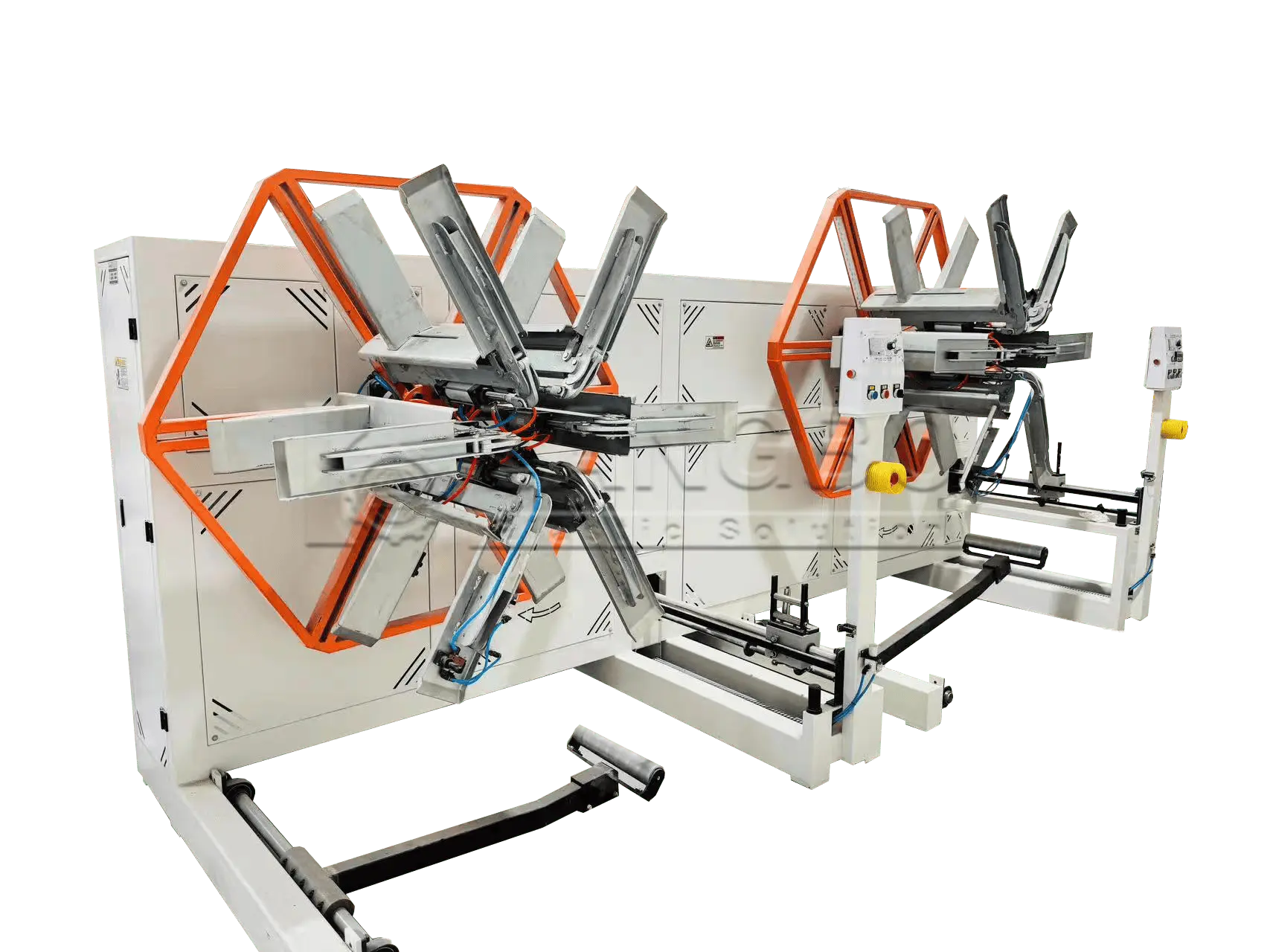

Suitabel for pipe 16-75mm

Servo motor for high speed and constant winding force

Touch screen and PLC control

Design of disk size can be client tailored by their packing size

Frequency inverter control for soft winding force to protect the corrugated pipe shape

Manual pipe discharging for keeping a small inner diameter of the final pipe roll

Winding disk size can be small

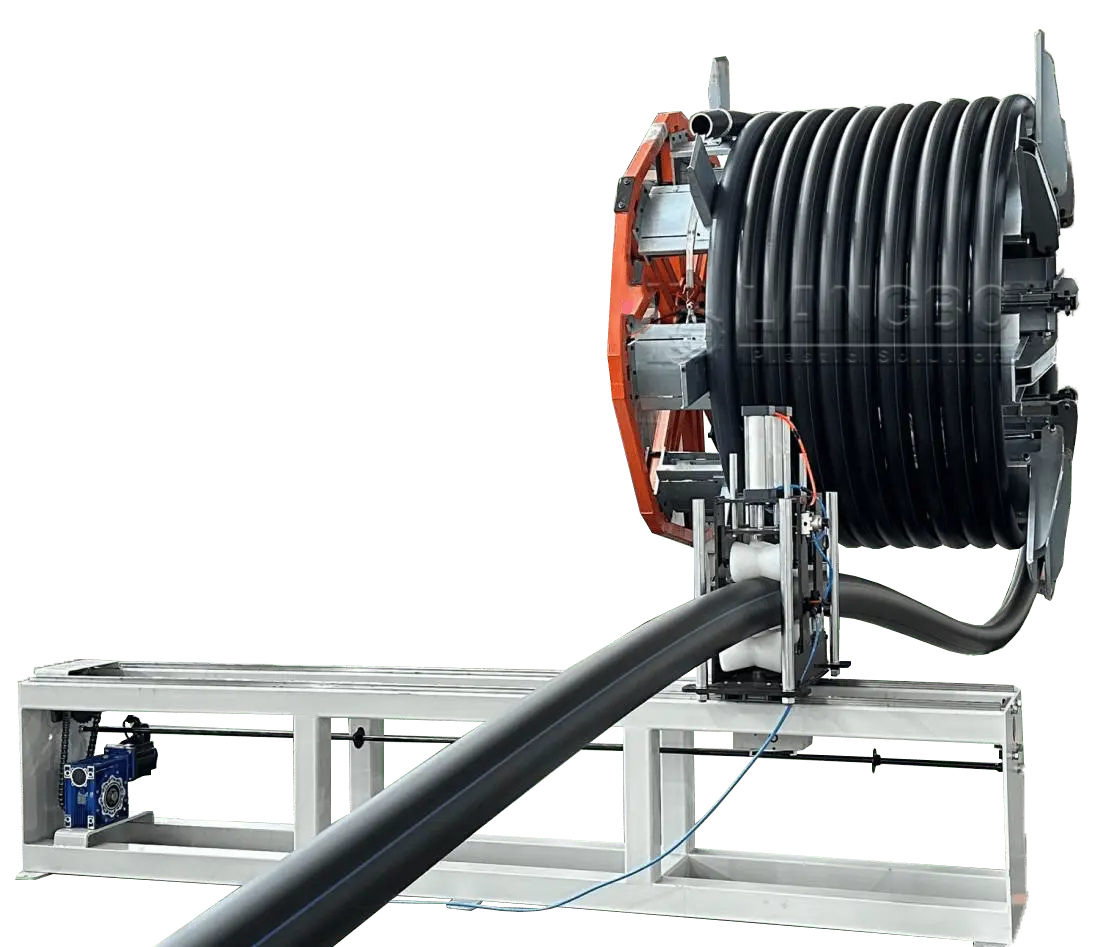

For pipe 50-110mm

Torque motor for low speed and constant winding force.

Standard design for disk size is for 100m length in a roll of the max pipe diameter

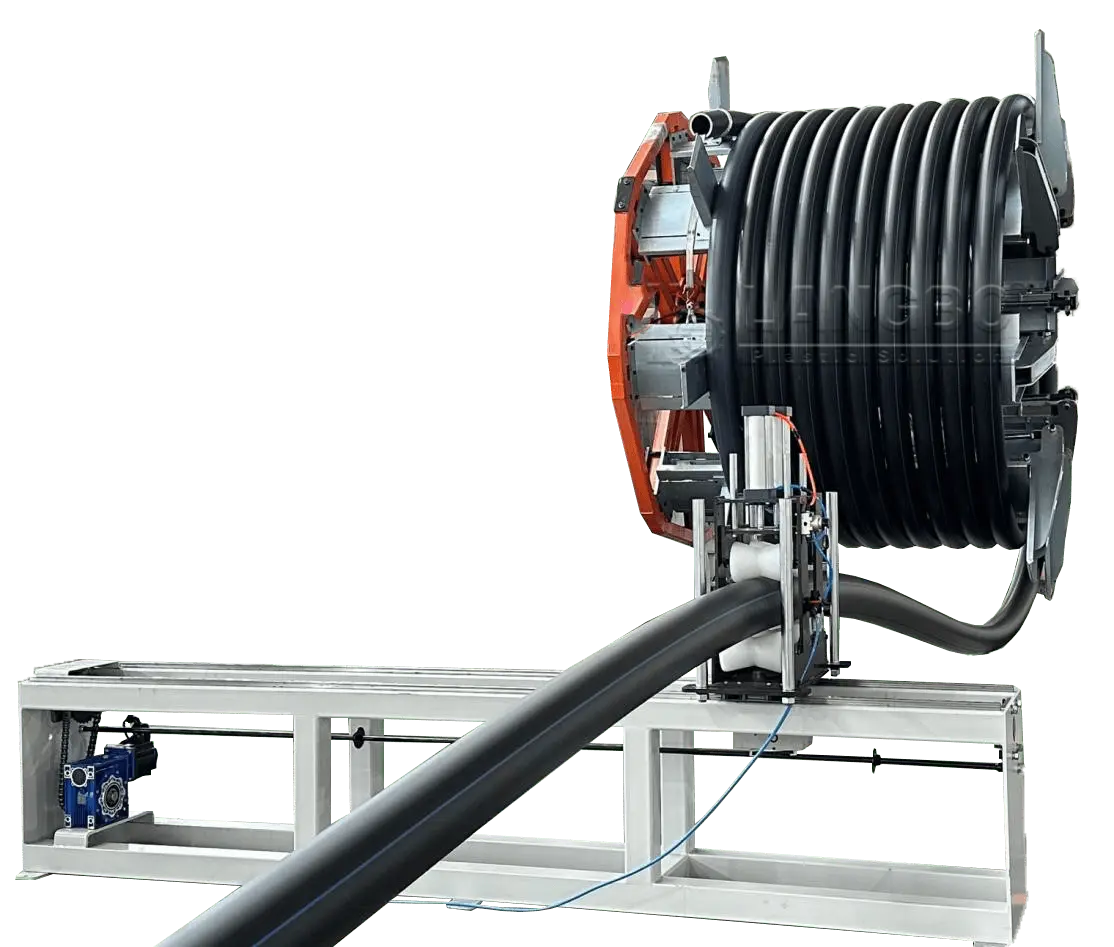

For pipe 63-180mm

Torque motor for low speed and constant winding force.

Standard design for disk size is for 100m length in a roll of the max pipe diameter

Coiler for soft window proof

torque motor driven

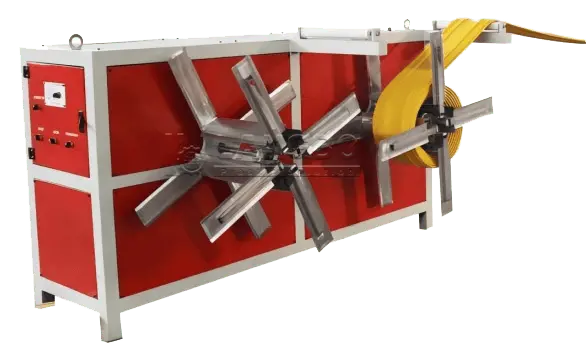

Double disk coiler for soft pipe