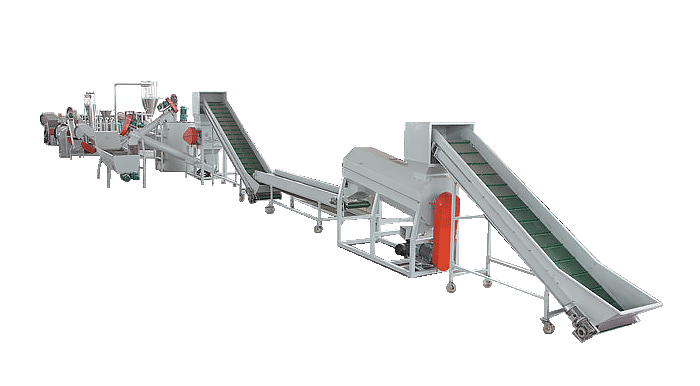

Before the bottle crushing the label on bottle should be removed. Our high efficiency label remover separates the label and cap, which are made NOT by PET material. This step filters out firstly the different material.

For a better cleaning effect, the PET bottle will be crushed into small particles. Small flakes will easier be cleaned with further steps. With different target material, the geometry and layout of crusher knife are different. The same is, that we use high quality alloyed material for knife to ensure a long and reliable working status.

This step and following steps will use different method to achieve two purpose: separation and cleaning of material. Here by the step of floating washer the PET flakes will be cleaned and transported by screw from the botton of tank.

With friction washer the wet pet flakes will contact each other in high speed to remove the other material on pet flakes.

To remove the chemical material on flakes such as glue. The chemical wash gel will be added in the hot washer. After this step the gloopy thing on flakes will be cleaned.

At this step the pet flakes and other material should be well cleaned. The device can separate the most of foreign material form the pet flakes. Besides that the flakes will be dried through air conveying and this device.