With caterpillar haul-off, the pipe will be quickly transported to the ready position and moved to the first heating oven. Comparing rollers the caterpillar makes a more reliable pipe transportation and avoid slip after several years using

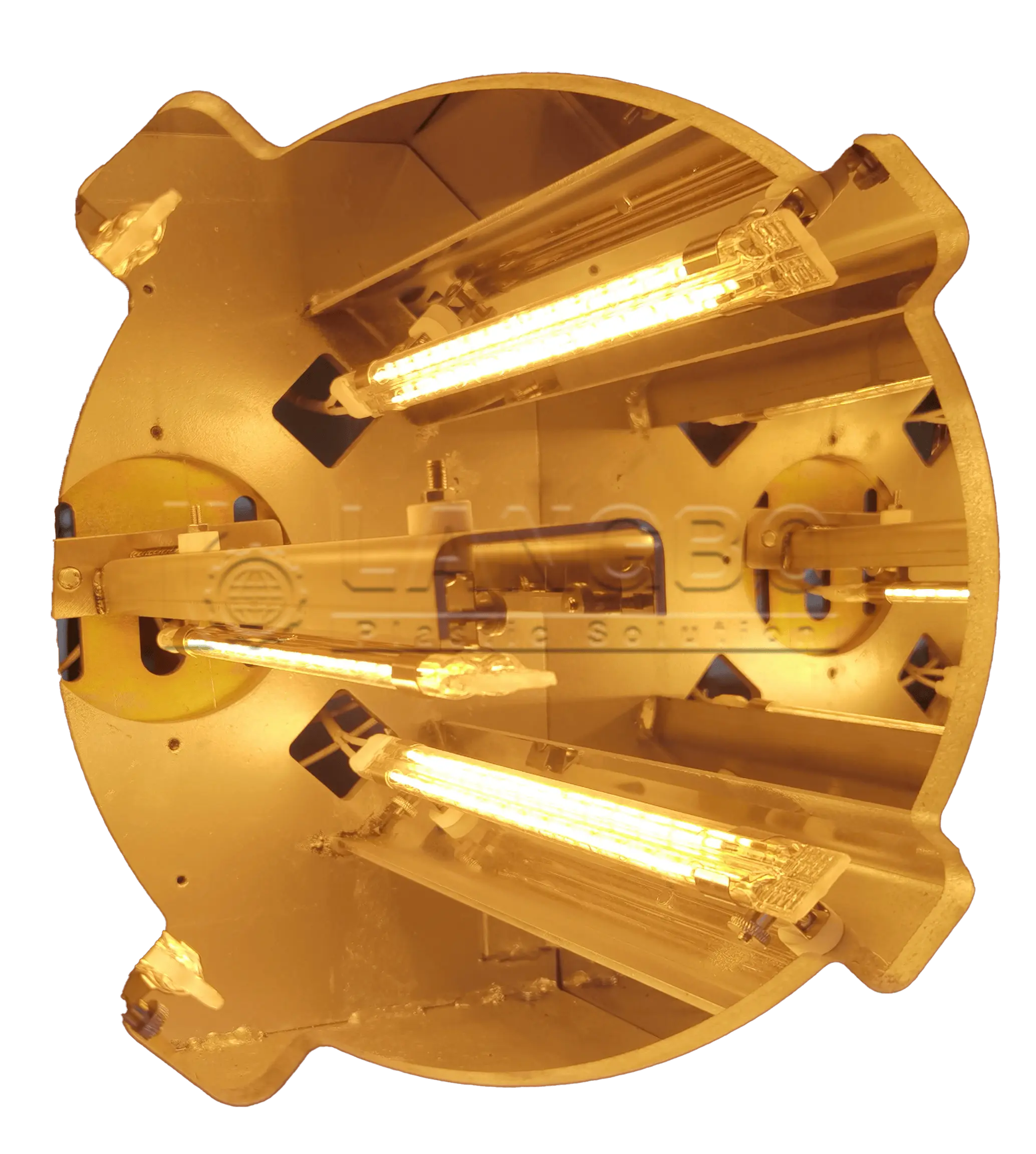

The heating lights will be turned off when there are no pipes in the oven. Also, the heating power is adjustable for different pipe diameter and different wall thickness.

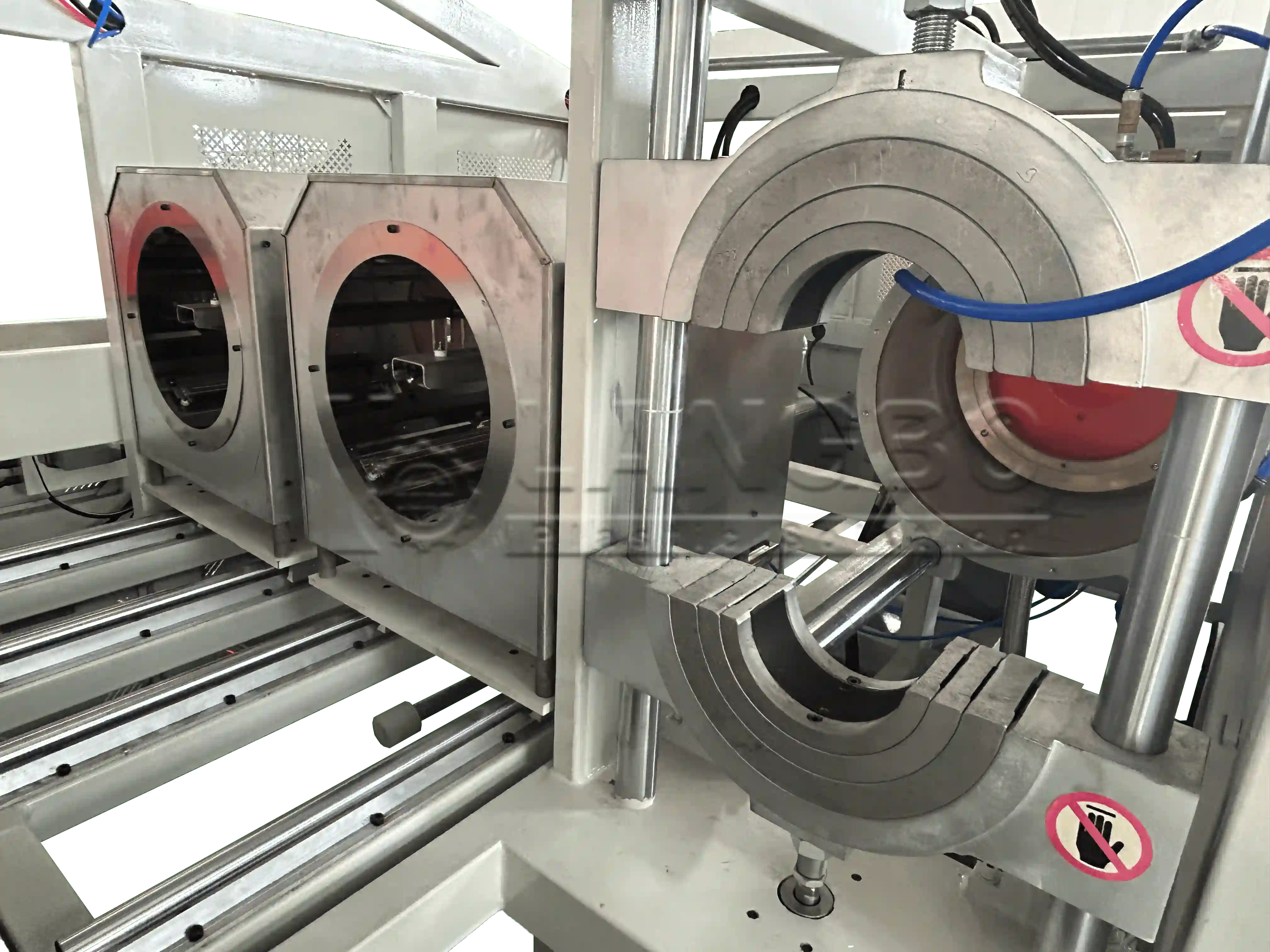

The first heating oven can be considered as a buffer position. Two ovens can balance the extrusion speed and heating time for pipe.

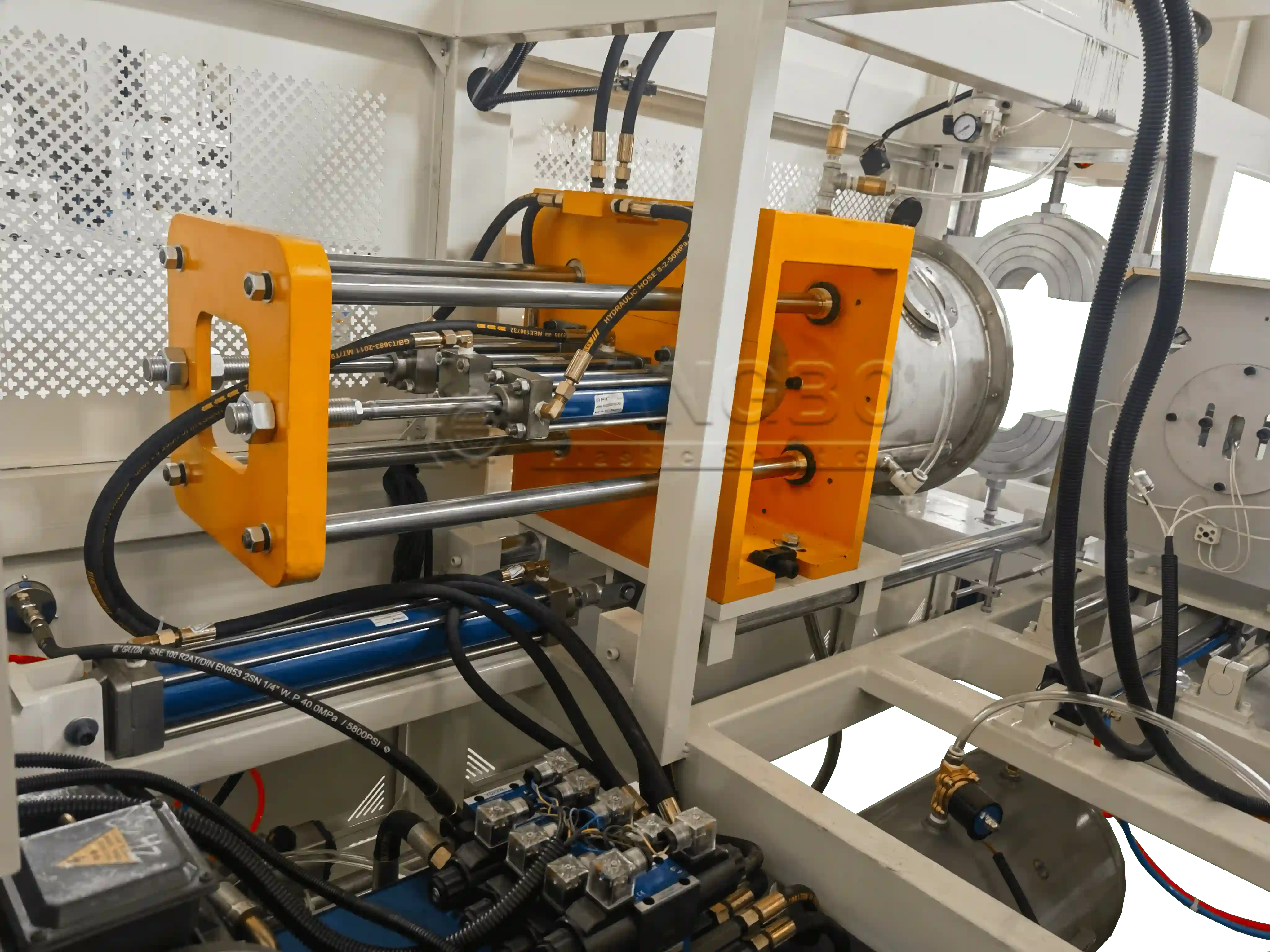

For diffrent pipe diameter and wall thickness, the clamping force must be different. With the knob on the operation side, the clamping force can be adjustment very easily

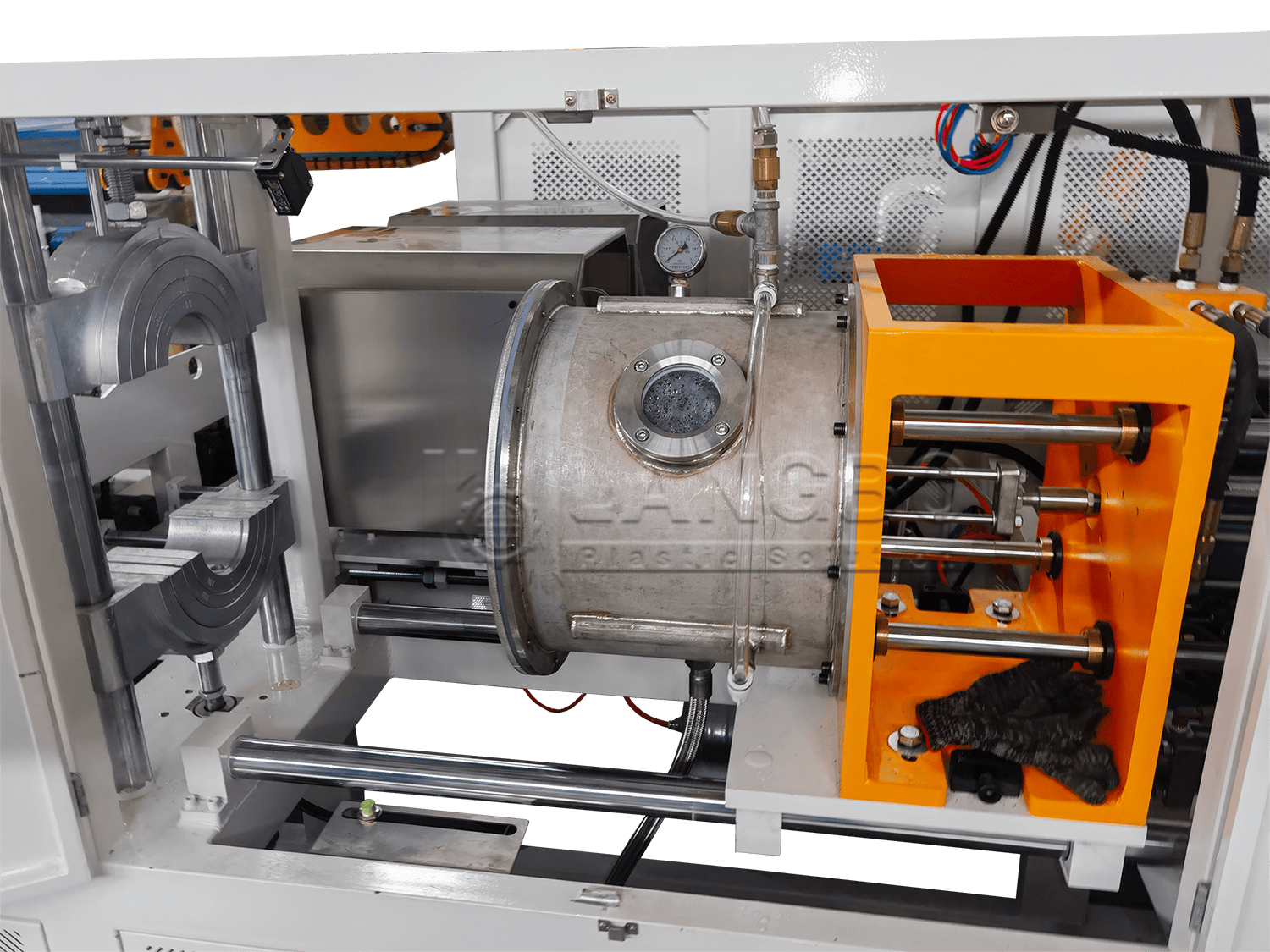

The after-socketing pipe must be cooled down by water. This is the key point for a perfect socket shape

The after-socketing pipe will be pushed by a hydraulic plate. This can

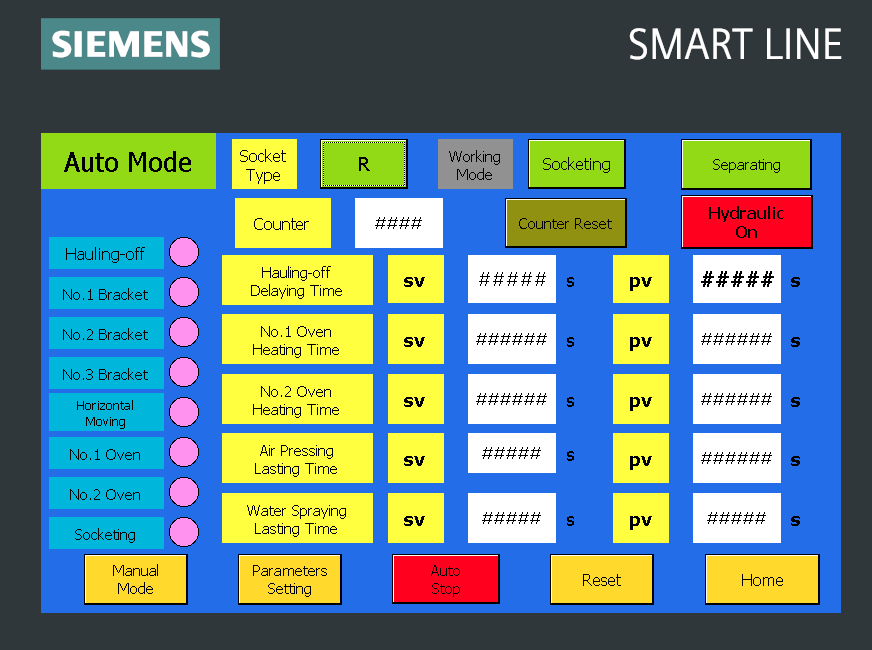

The touch screen shows all the process flow and current process step. Operators can modify the parameter and monitor the whole process