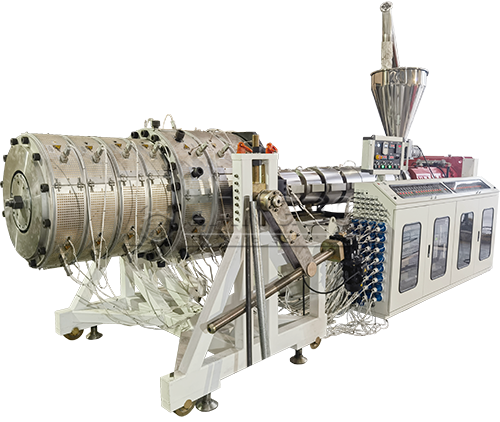

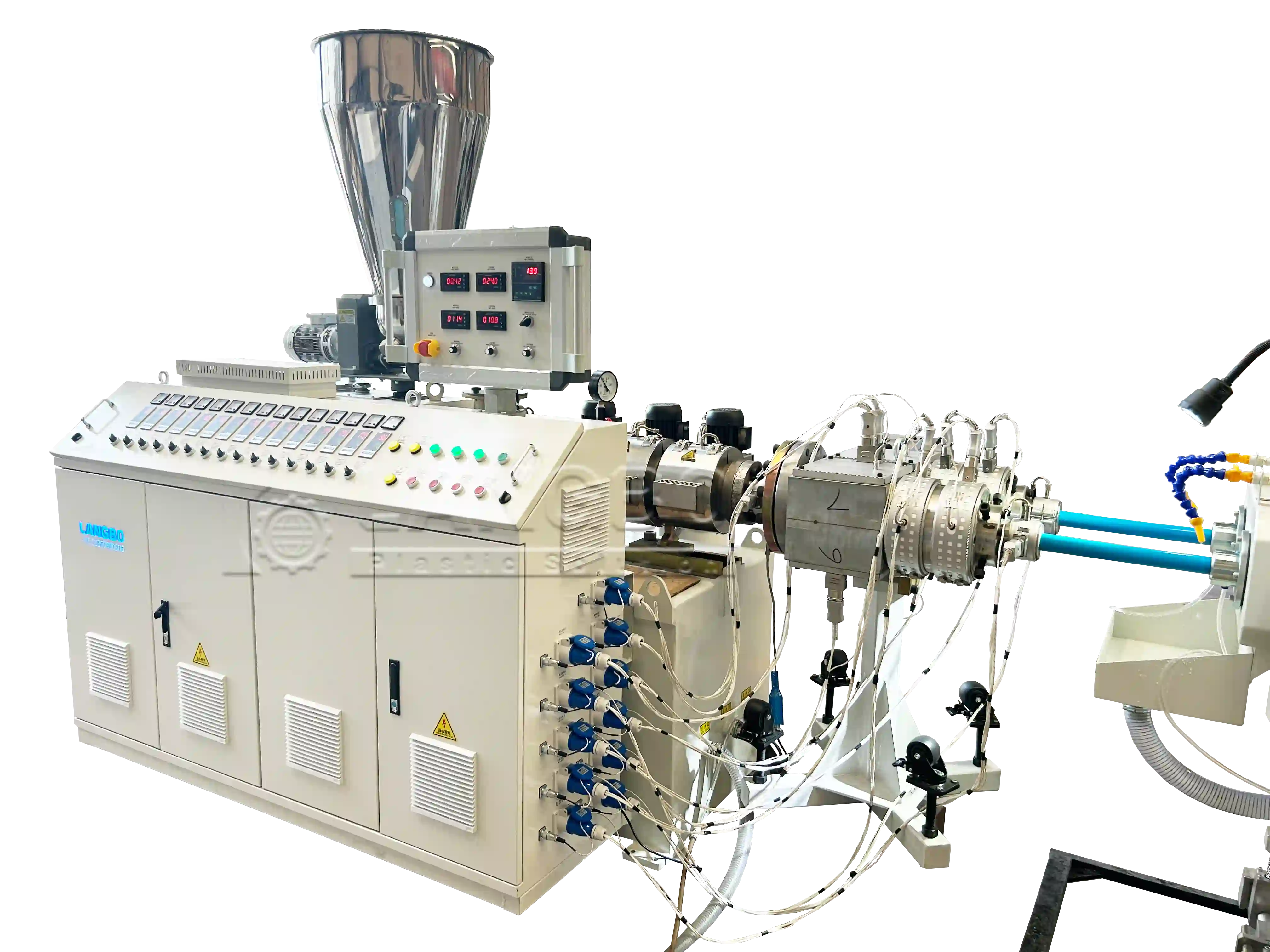

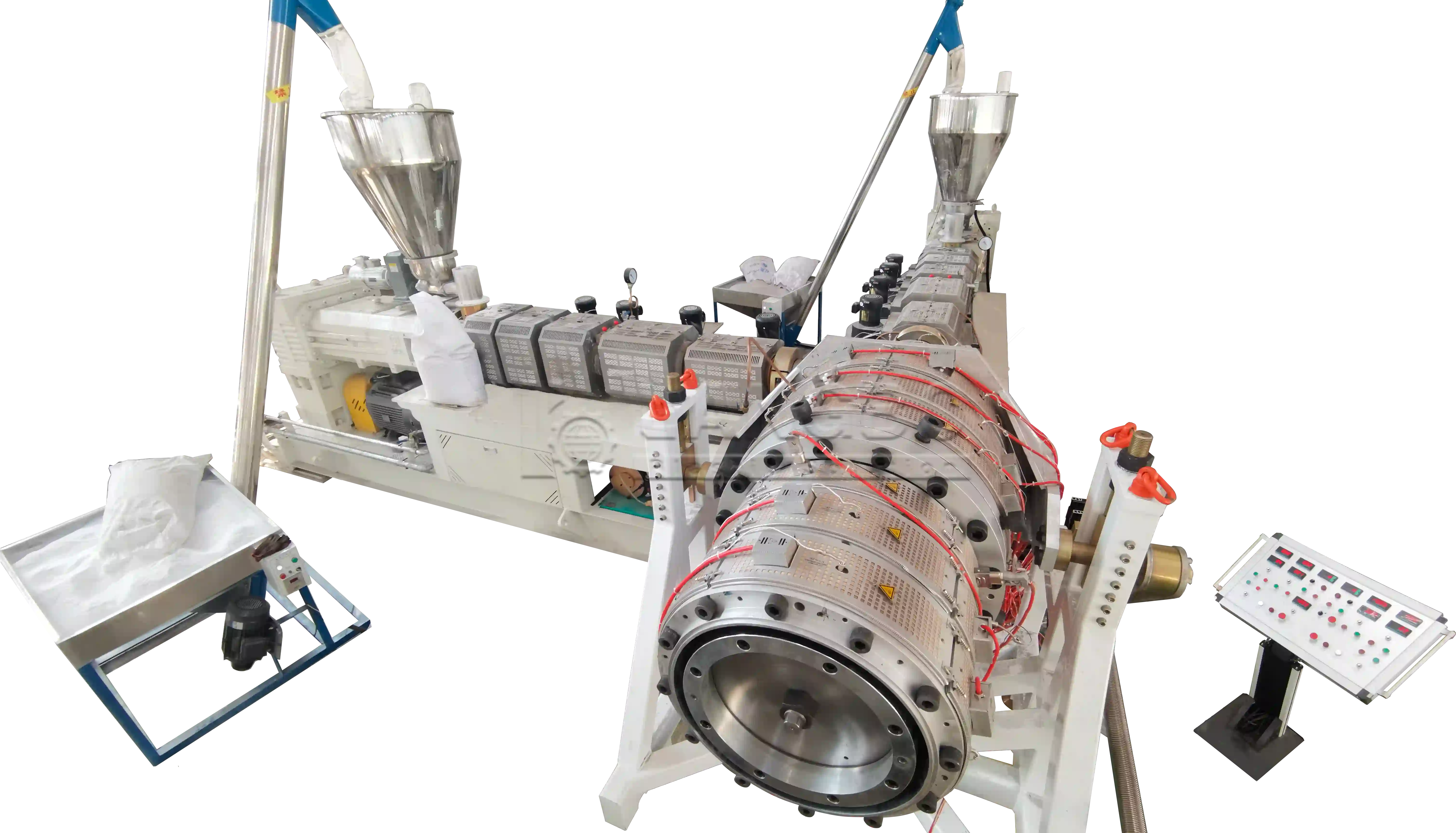

Various combination of extruders guarantees the extrusion volume for large pipe production

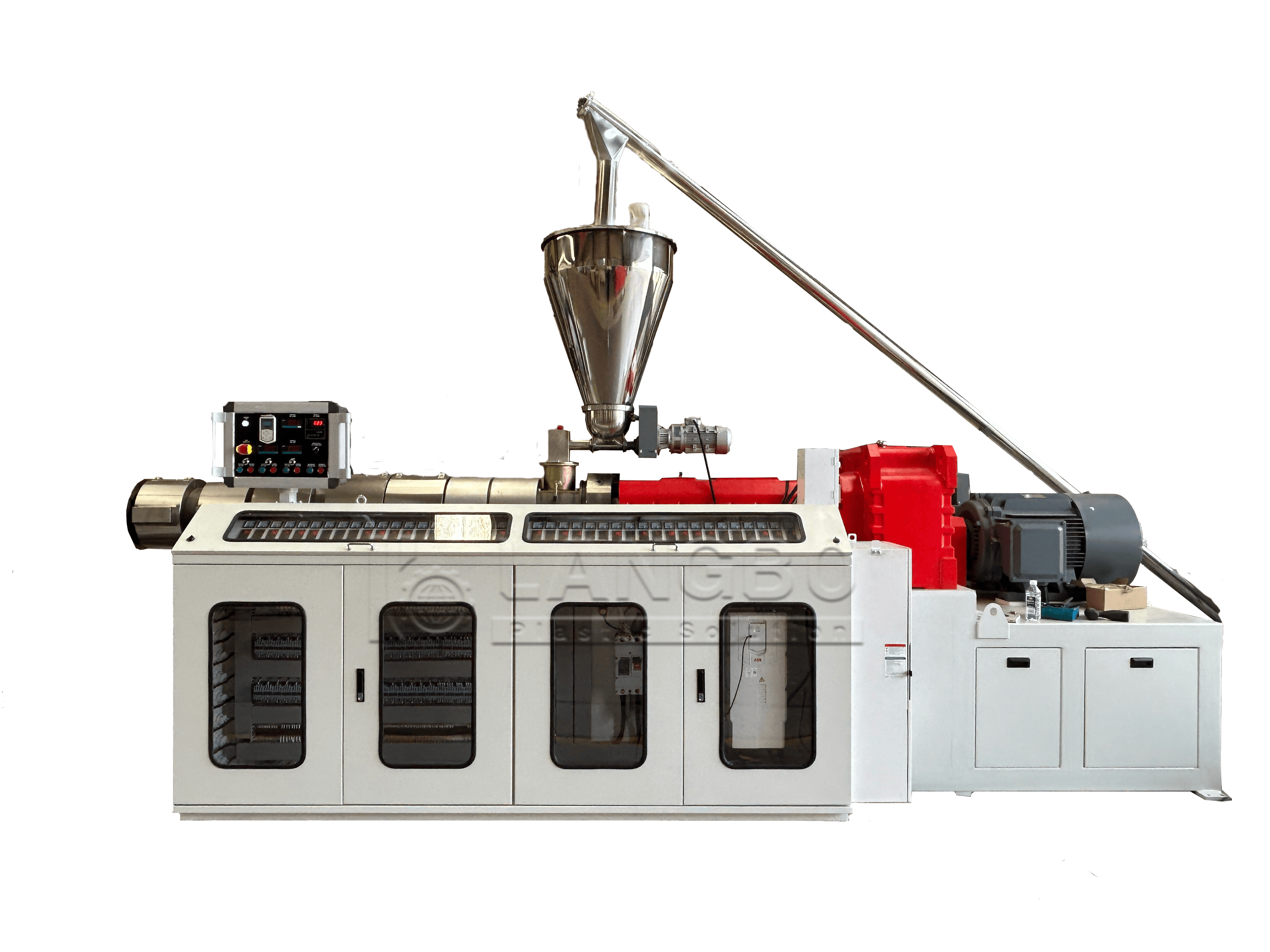

Permanent magnet synchronous motor for reducing 10%-20% energy consumption comparing with DC or AC Motor.

Core parts in extruder provided by Worldwide famous suppliers for reliable production

Easy Temperature setting and indication

Easy operation and parameter monitoring on control panel

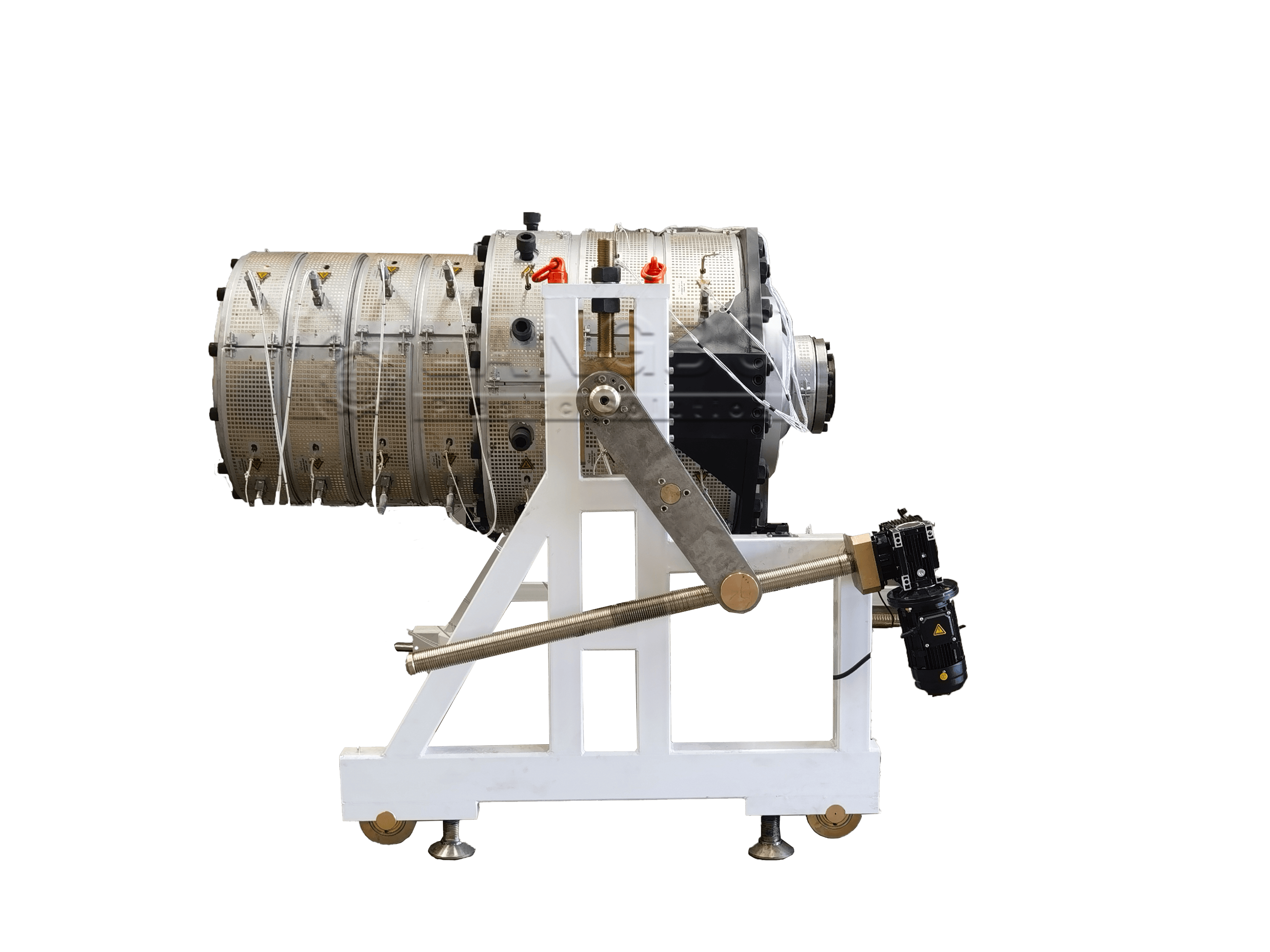

Specially designed of flow channel for superb pipe shaping and reasonable melt pressure

Big mould body and double stage compression design for stable extrusion and high pipe pressure standard

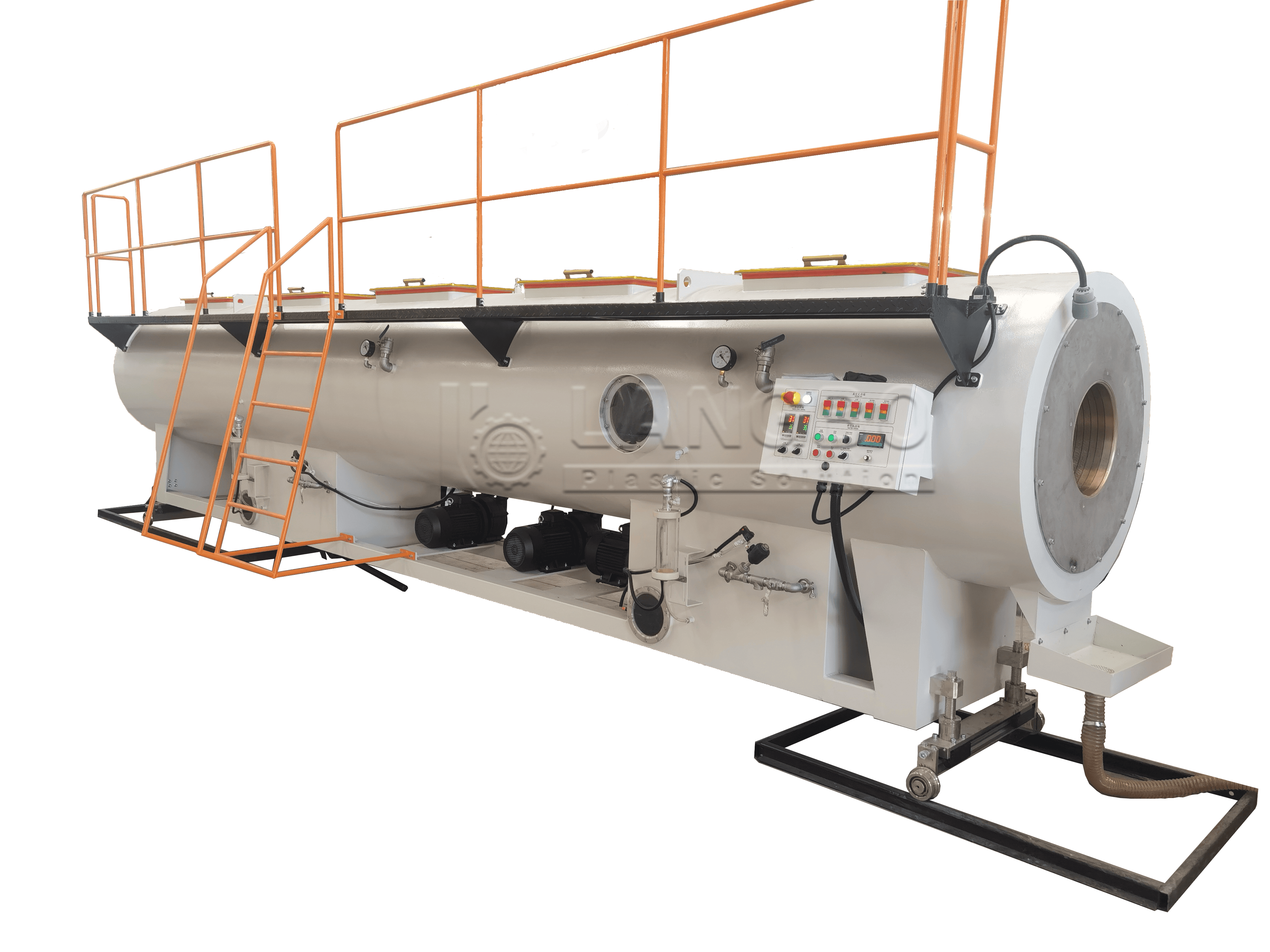

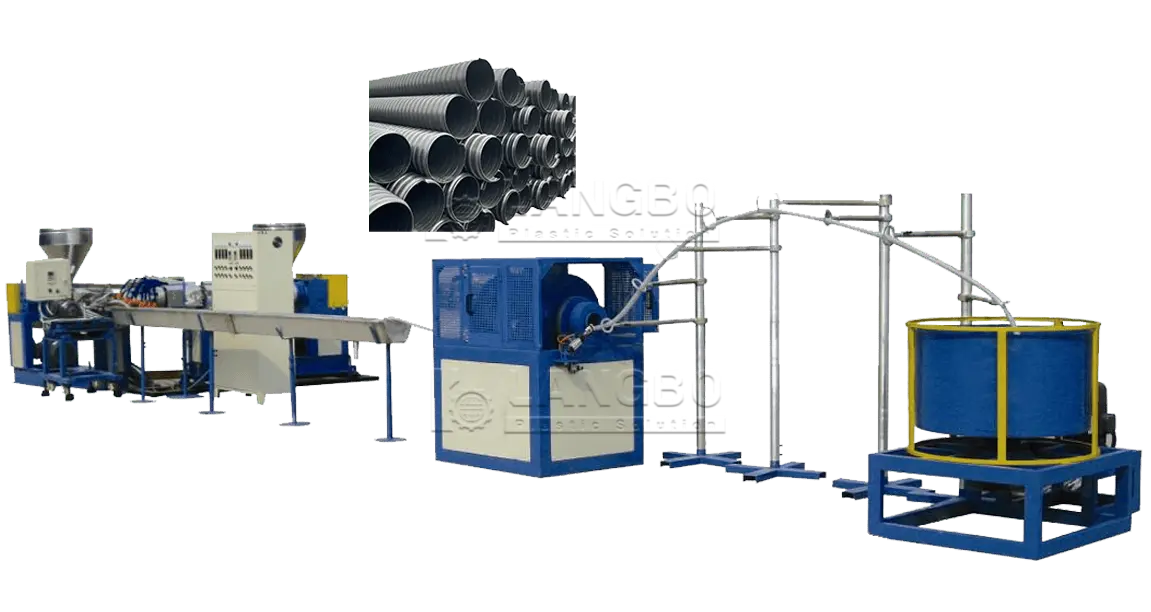

Vacuum Pumps driven by AC Drive to realize a constant vacuum environment and high energy efficiency

Robust concept of components for stable running

Advanced manufacture technology for robust structure and precise adjustment

Constant vacuum grade controlled by frequency inverter as optional

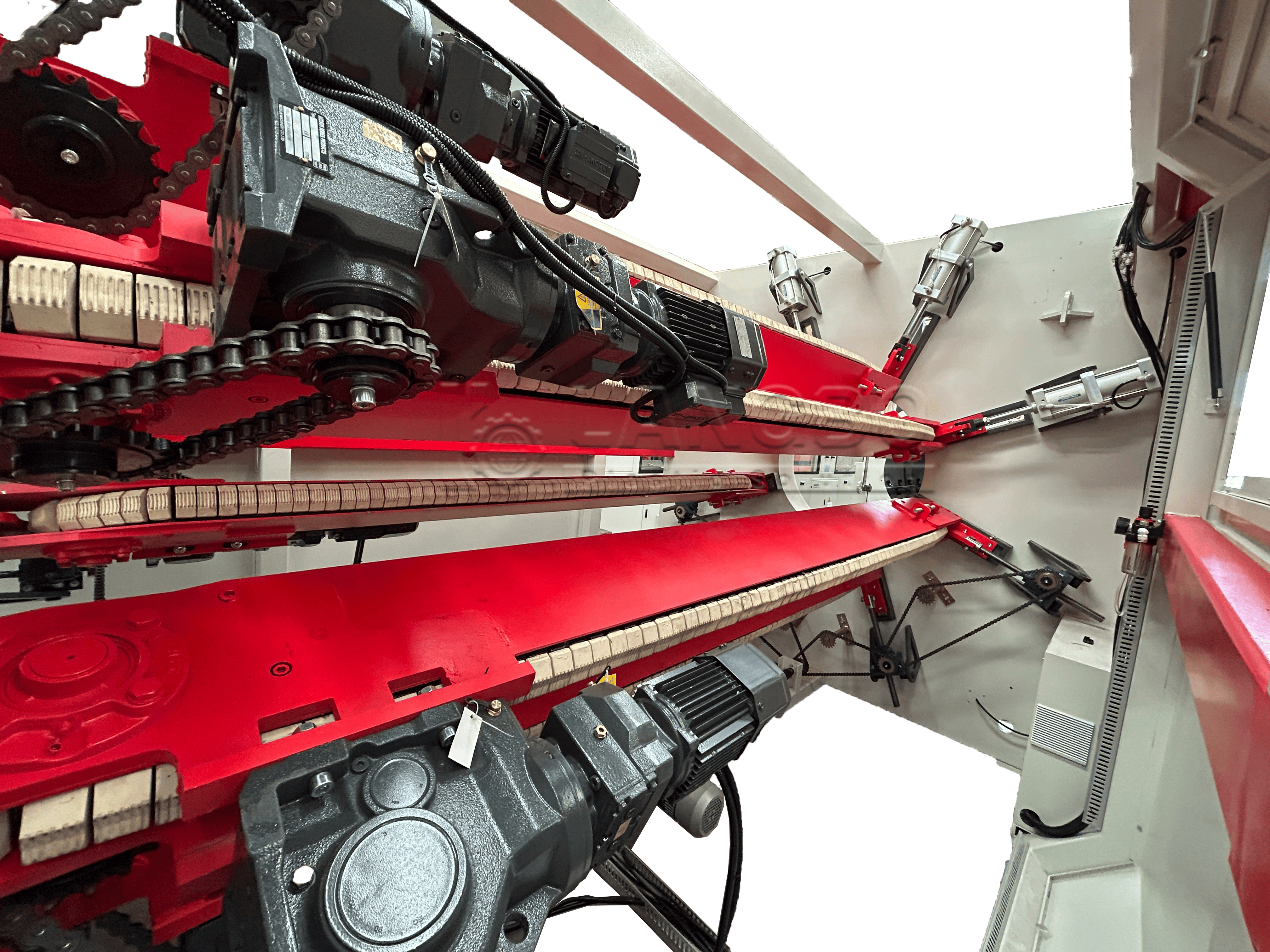

Servo motor and high-quality reducer for synchronized movement of caterpillars

Tailored hauling concept adopted based on certain production requirement

Optimized design for easy maintenance and mechanical repairment

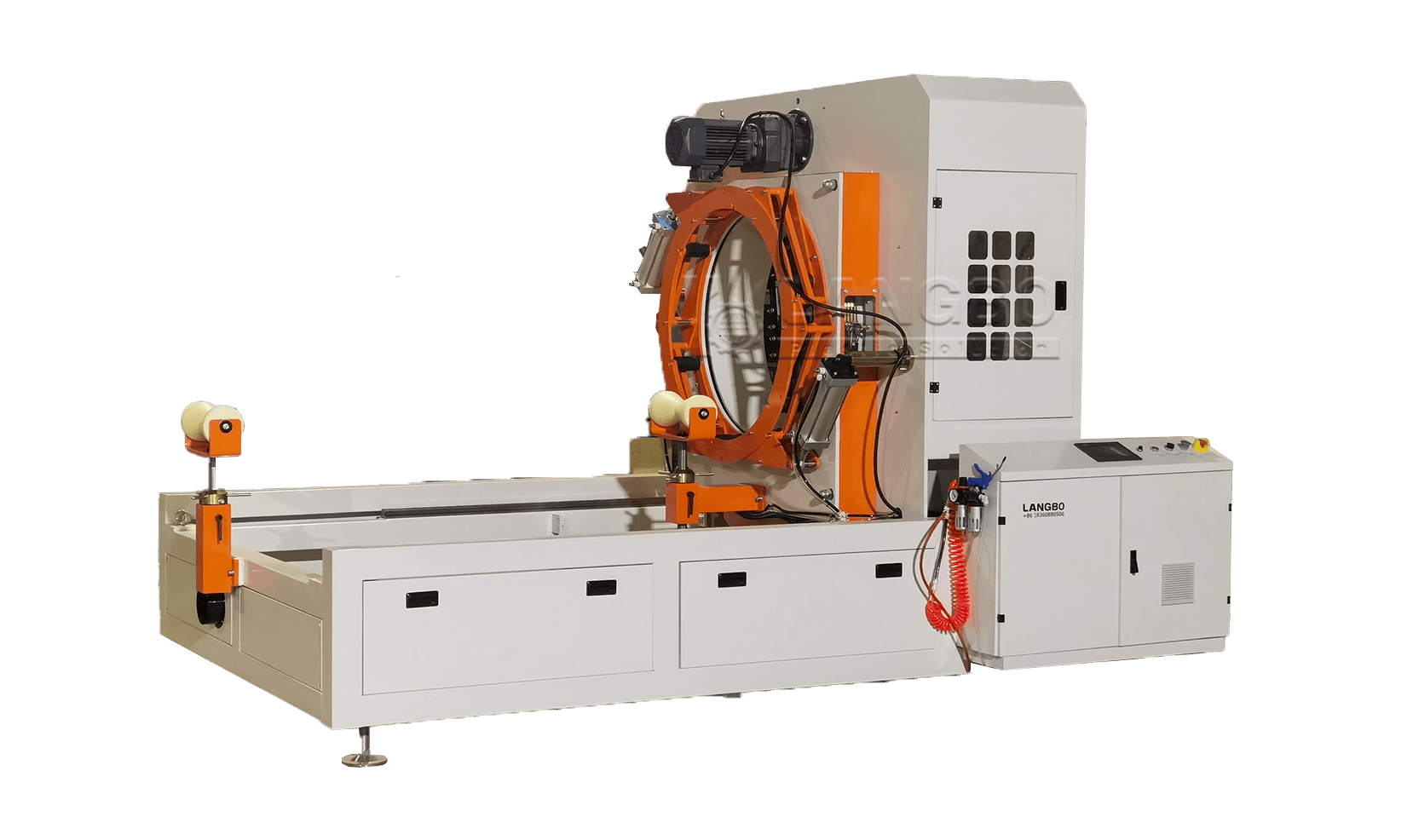

Chamfering during planetary cutting

Hydraulic saw feeding and synchronous belt for saw driving for stable and long working time

Cutting machine with frame ensures a stiffer structure and better cutting process

Suitable cutting concept based on production requirement

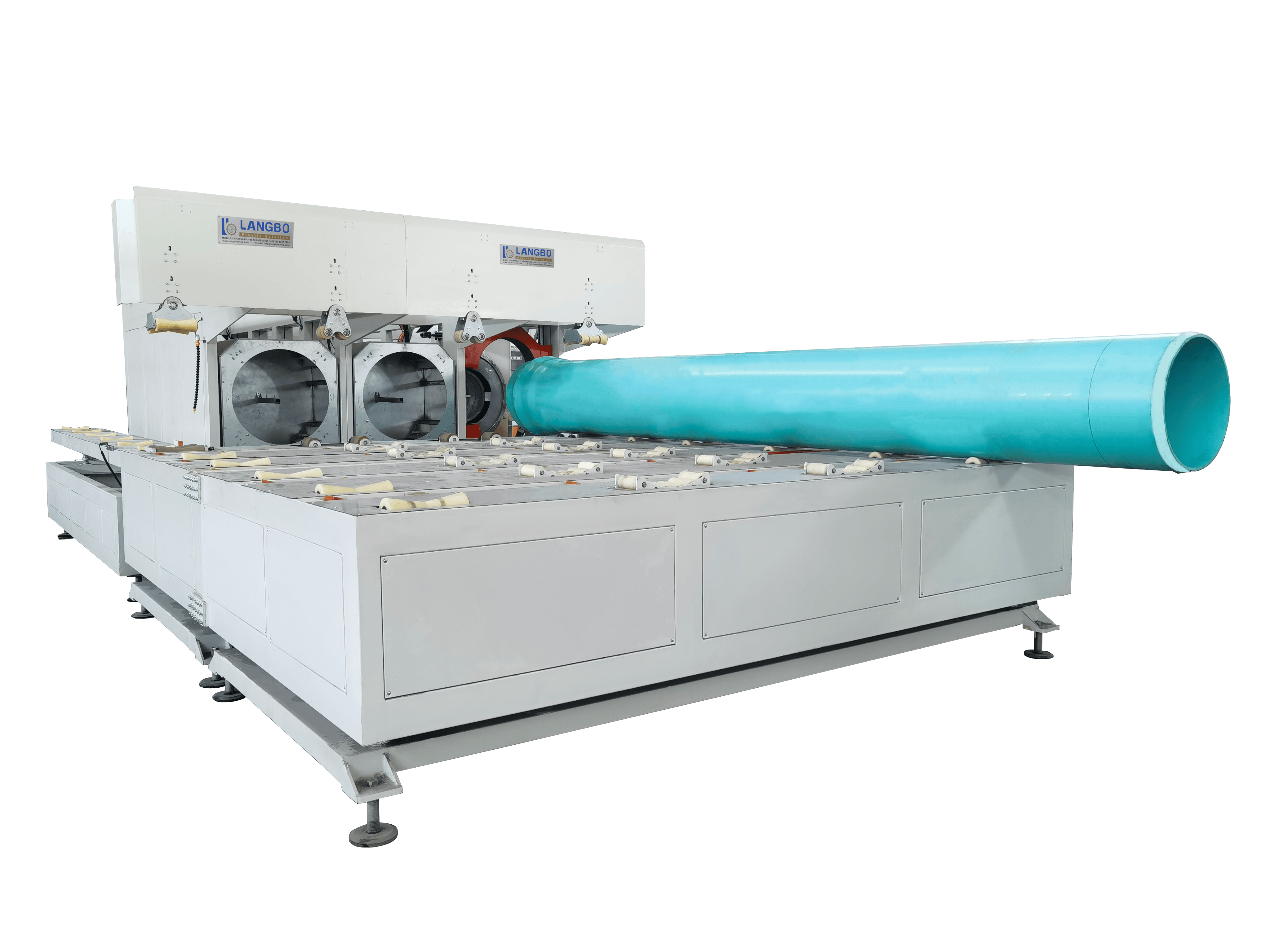

Two heating positions for on-time belling with high line speed

Energy saving by automatic switch of heating element

Water cooling concept and hydraulic socketing concept for stable socket forming

For unsocketed pipe the hole can hold the pipe directly