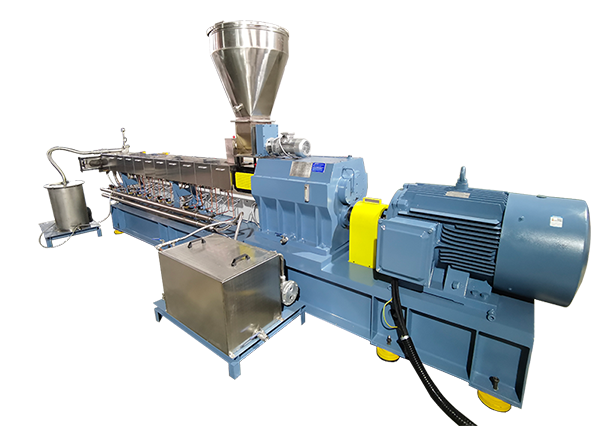

Based on the customized production plan we have different extrusion concepts for choice. The Parallel Twin Screw Extruder is based on our experience mostly applied extrusion solution, which combines with underwater granulating device.

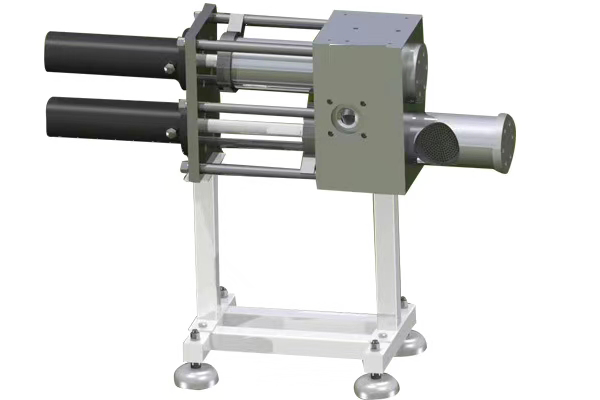

Screen changer is used for cleaning contaminants in melt (sand, metal, different plastics) which reduce granule quality. There are different kind of screen changer such as single- or double- plate screen changer and single- or double-cylinder screen changer. Based on different working condition the suitable screen changer will be adopted.

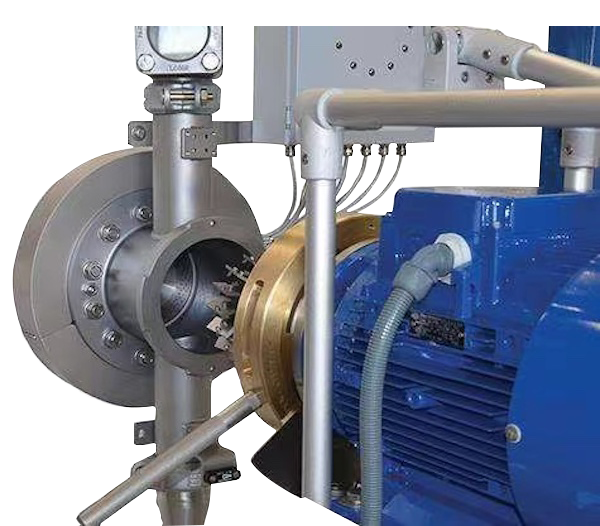

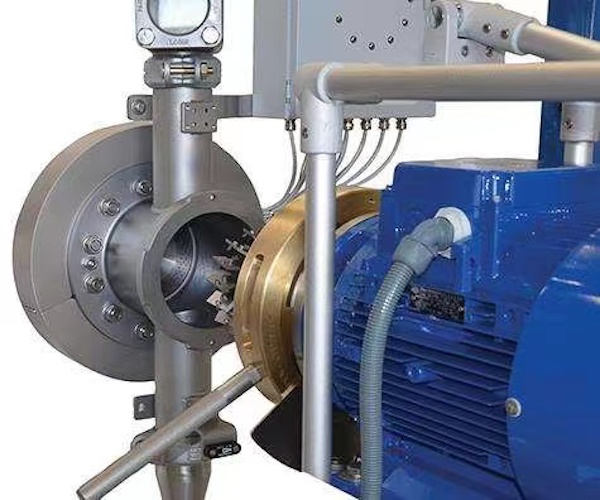

Contact pressure between rotary knife and die face is monitored for long cutting time and high quality of granules. The rotation speed of knife is based on melt pressure and automatically adjusted. The rotary knife device is adjustable for maintenance. The easy replacement of knifes saves time by maintenance.

It separates the granules and water. The Granules will through centrifugal drying be transported from the bottom to top of dewatering device. During the lifting the moisture will be effectively reduced.

The vibration sieve filters out the granules with its size. Too big or small granules will be filtered out. Only the right size will be transported in the storage silo.

Final Granules will be stored in silo. Based on demand the on-line monitoring and weighting system will can be applied.