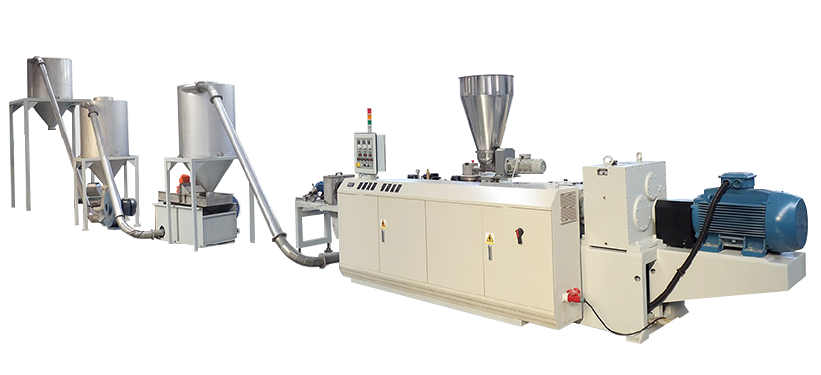

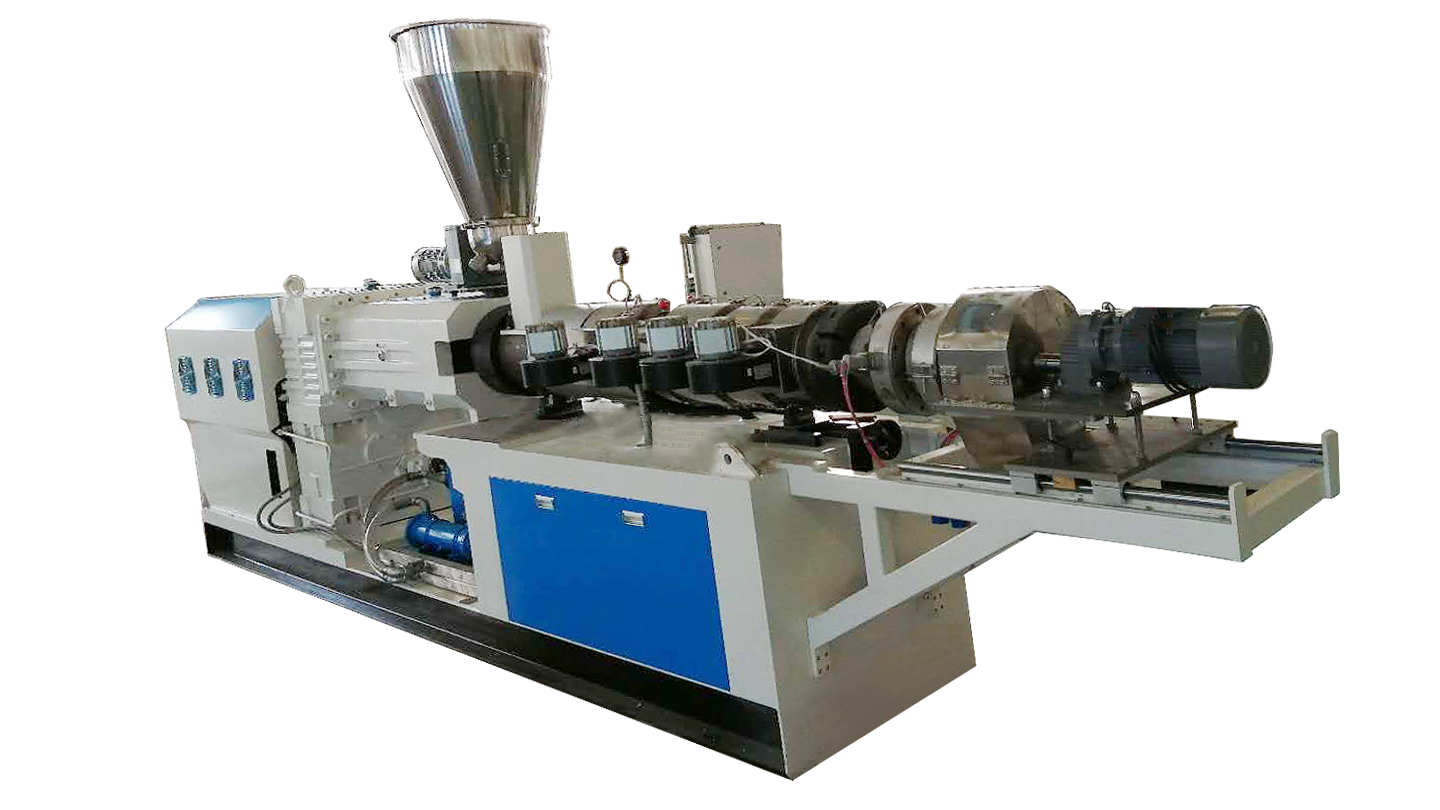

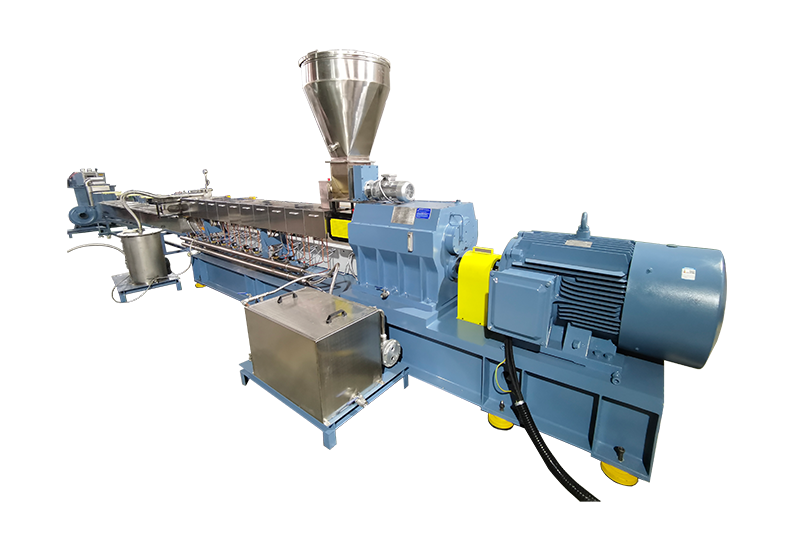

The Design and manufacture of screws for processing of dry powder blend

High quality screws and barrel for long service time

Permanent magnet synchronous motor for high energy efficiency

Operator oriented operation logic for clever and easy operation during production

Touch screen (optional) for an integrated information management and easy operation

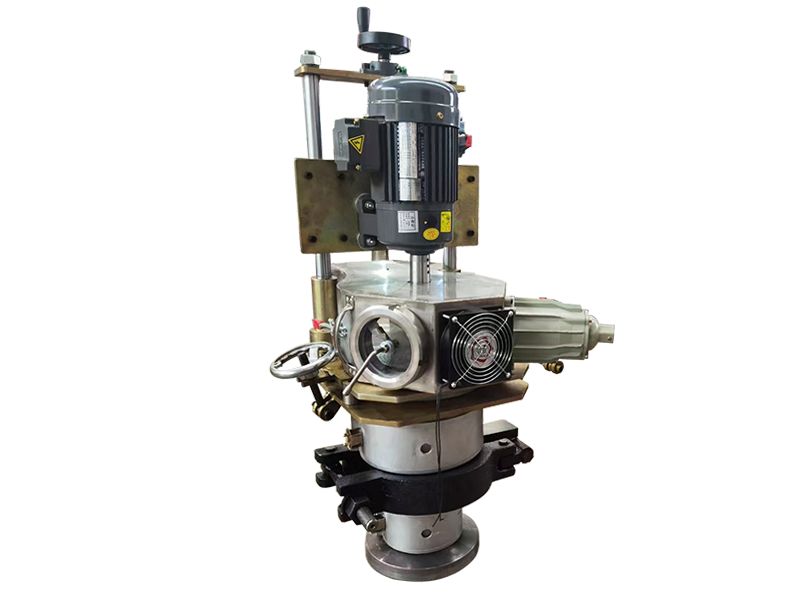

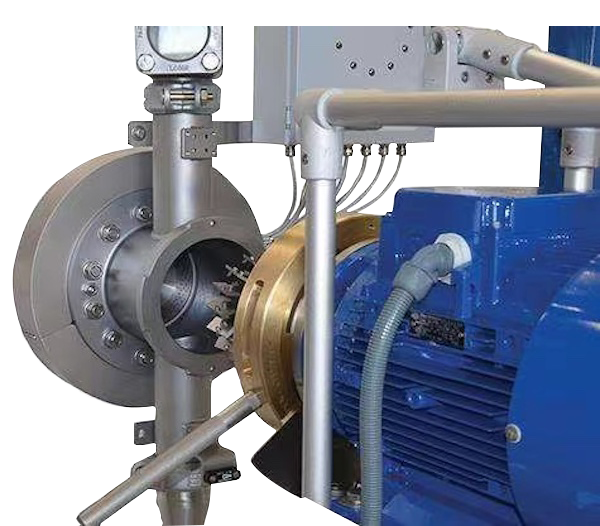

Contact pressure between rotary knife and die face is monitored for long cutting time and high quality of granules. The rotation speed of knife is based on melt pressure and automatically adjusted. The rotary knife device is adjustable for maintenance. The easy replacement of knifes saves time by maintenance.

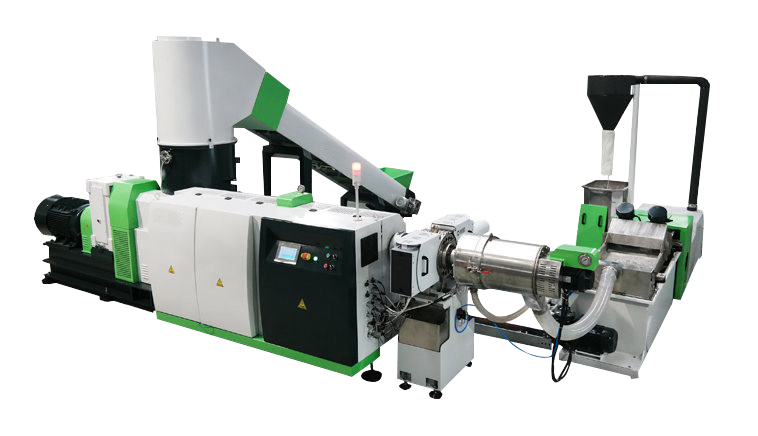

For PVC Granulating the air blower can cool down the PVC Granules to storage temperature. With one or multi-stage air cooling the granules will be transported to the vibration sieve.

The vibration sieve filters out the granules with its size. Too big or small granules will be filtered out. Only the right size will be transported in the storage silo.

Final Granules will be stored in silo. Based on demand the on-line monitoring and weighting system will can be applied.