India

PE Irrigation Pipe Line

The line runs steadily and meets our requirements for daily irrigation pipe production.

HDPE

HDPE Pipe

Pipe Extrusion

Municipal Pipe

HDPE Pipe Extrusion Line-production with DN16-DN63

Highlights

Stable extrusion performance for PE irrigation pipes

Consistent pipe diameter and wall thickness control

Reliable operation under long-term continuous production

Flexible configuration for different irrigation pipe specifications

Tailored Solution

01.

Extruder

The extrusion system was configured for PE material with a screw design optimized for stable melt plasticization and smooth output. Temperature zones were adjusted to ensure consistent extrusion during continuous operation.

02.

Mould

The mould was selected according to the irrigation pipe diameter range and pressure rating. Balanced flow design helps achieve uniform wall thickness and good surface quality.

03.

Vacuum Calibration

A vacuum calibration tank was applied to ensure accurate pipe sizing and roundness. Adjustable vacuum levels allow stable calibration for different pipe diameters.

04.

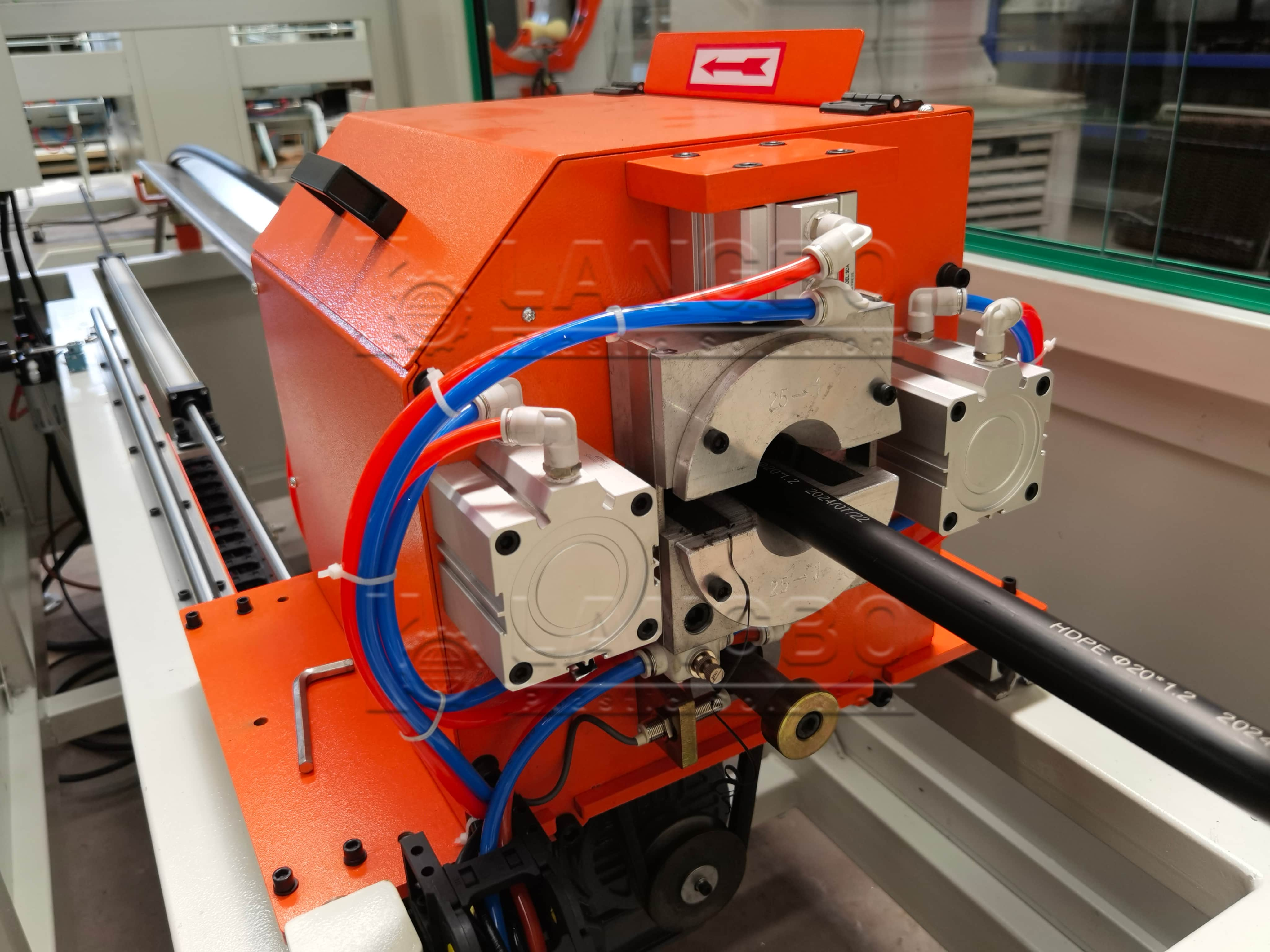

Haul-off Unit

The haul-off unit provides stable pulling force with synchronized speed control. The design ensures smooth downstream handling without pipe deformation.

05.

Cutting Unit

A flying cutting system was used to achieve accurate length cutting without interrupting pipe extrusion. Clean and square pipe ends support easy downstream handling and packing.