United Kingdom

PE Multilayer Pipe Extrusion Line

The multilayer PE pipe line operates smoothly with high stability. Pipe quality, wall thickness consistency, and production output fully meet our expectations.

HDPE

HDPE Pipe

Pipe Extrusion

Municipal Pipe

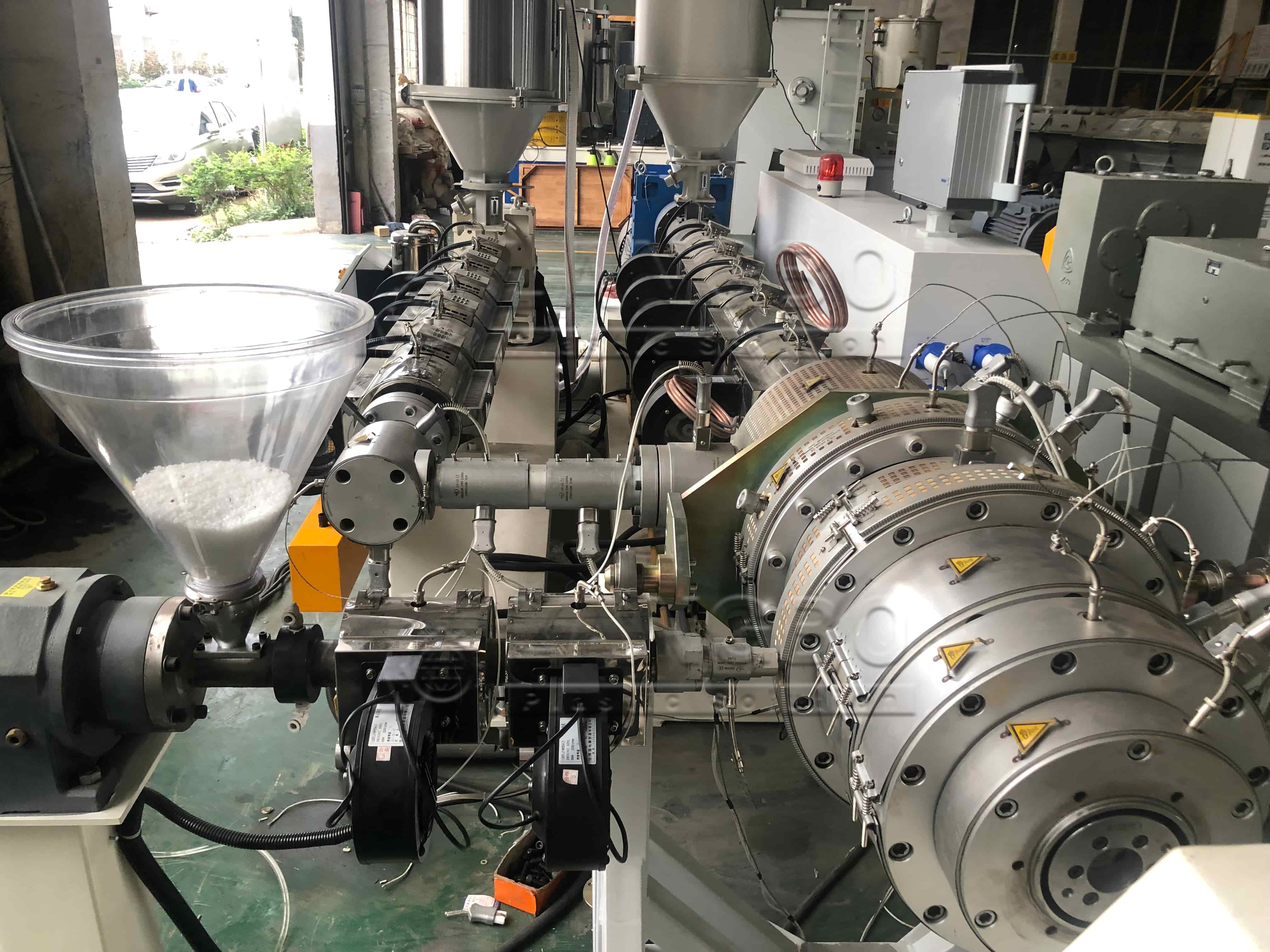

75-315mm ABA HDPE Pipe Extrusion Line

Highlights

Stable extrusion for multilayer PE pipes

Accurate layer ratio control for consistent pipe performance

Uniform wall thickness and diameter control

Suitable for continuous production of various pipe sizes and specifications

Tailored Solution

01.

Main Extruders

The line consists of two single-screw extruders: one extruder for the inner layer and two extruders for the outer layers. All extruders are crafted with top-brand components to ensure production stability, high efficiency, and long-term machine durability. They feature international standard single screws and barrels, with screws designed for high rigidity, providing a long service life and excellent plasticizing performance.

02.

Mould

A multilayer co-extrusion head with spiral distribution moulds ensures uniform melt flow and precise wall thickness across all layers, guaranteeing high pipe quality and dimensional accuracy.

03.

Vacuum & Cooling Tank

Multi-section vacuum calibration and cooling tanks provide stable pipe shaping, effective diameter control, and optimized cooling for consistent wall thickness. Zones can be adjusted according to pipe size and layer structure.

04.

Haul-off Unit

A synchronized haul-off system maintains stable pipe pulling speed, ensuring smooth continuous operation and minimizing dimensional deviations.

05.

Cutting Unit

A planetary cutting system enables continuous cutting without stopping the line, producing clean, smooth pipe ends suitable for various applications.