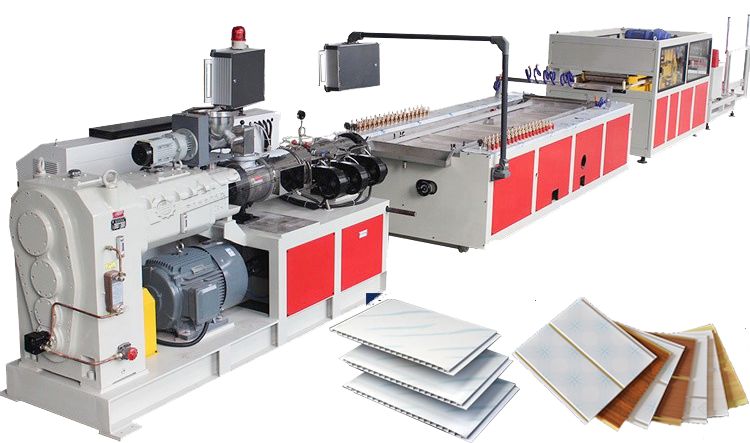

The Design and manufacture of screws for processing of dry powder blend

High quality screws and barrel for long service time

Permanent magnet synchronous motor for high energy efficiency

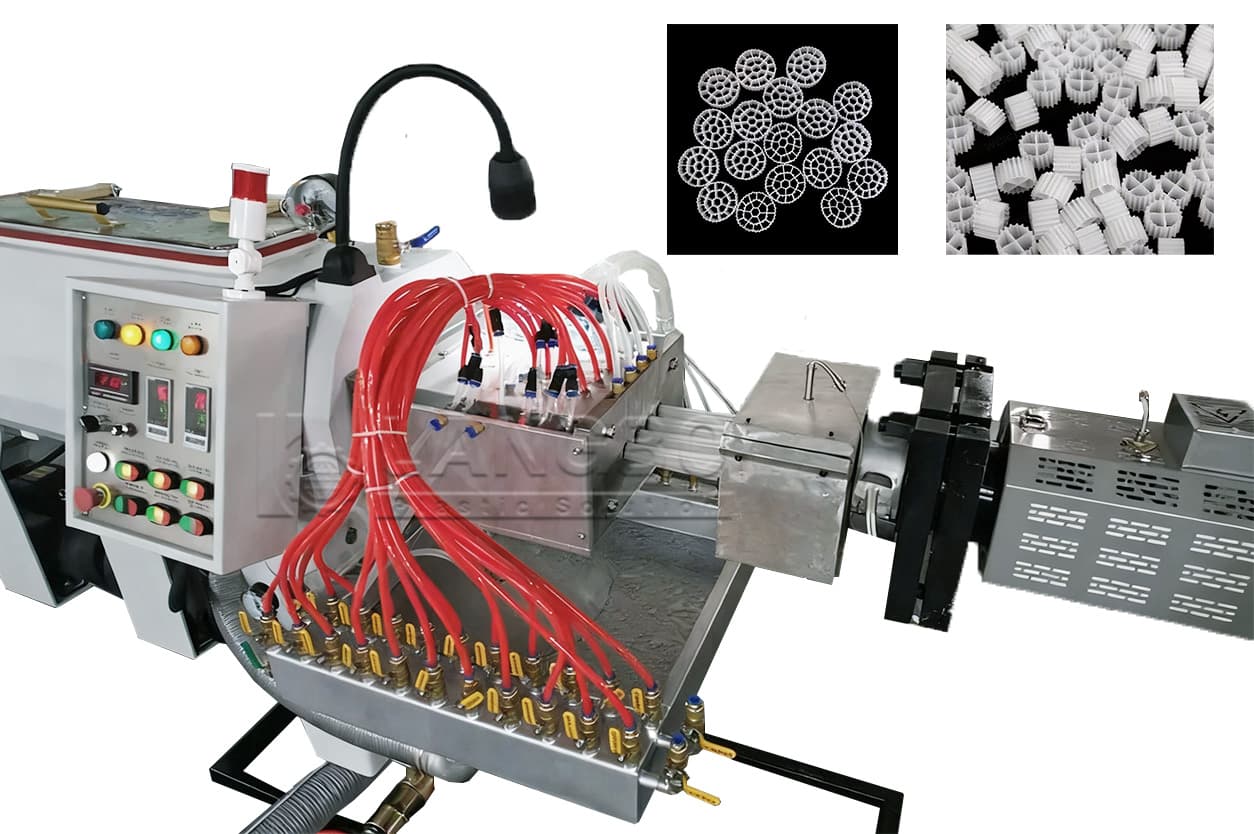

Operator oriented operation logic for clever and easy operation during production

Touch screen (optional) for an integrated information management and easy operation

High flow performance due to optimized channel design

Manufactured by advanced machine tool with high precision

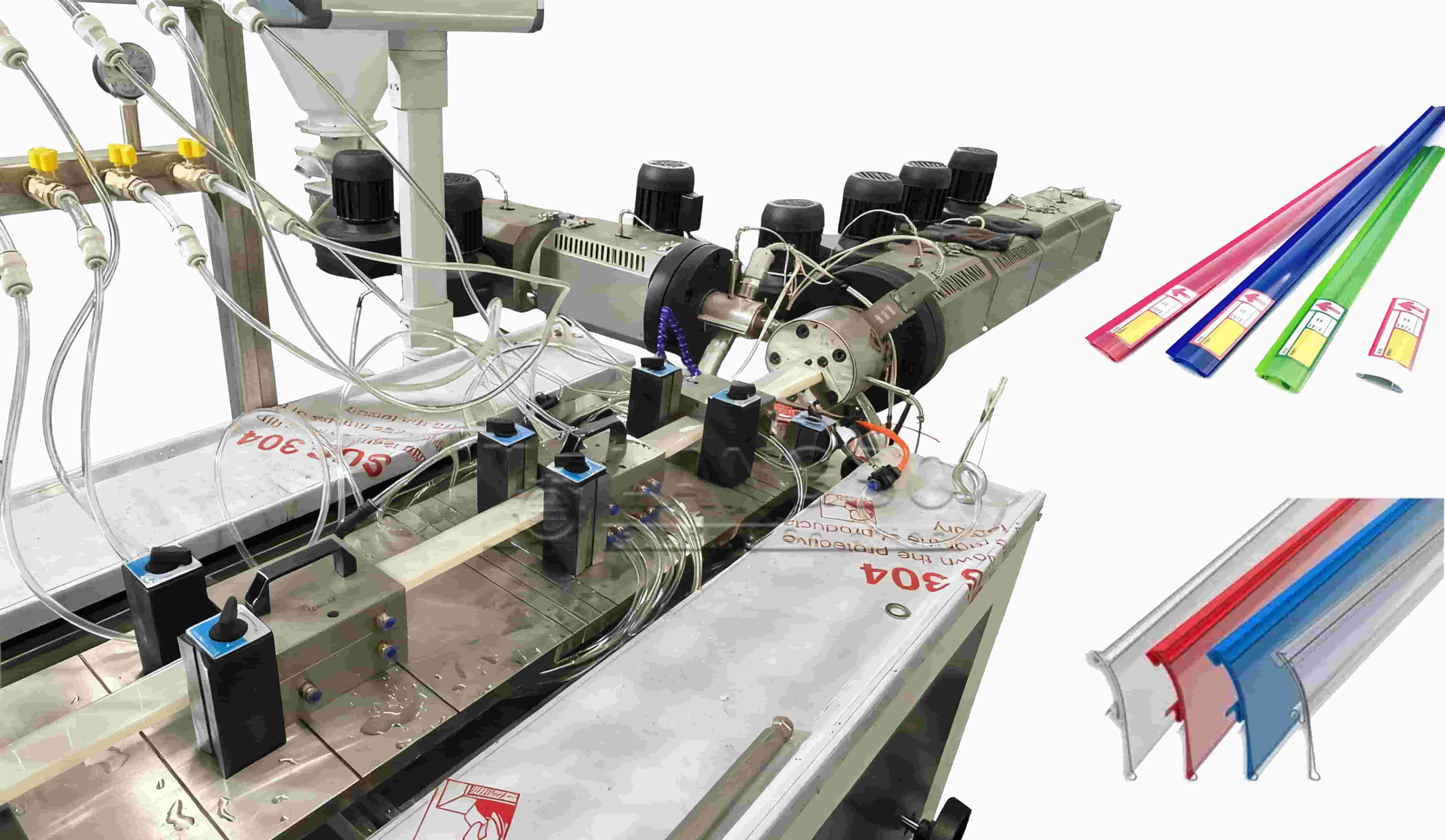

Sturdy steel frame and high-quality body material like SUS 304 stainless steel

Multi-dimension position adjustment system

Operation optimized water circuit system for energy saving

Optimized layout of valves for vacuum and water for rapid shaping and cooling

Easy operation and synchronization for controlling the extruder

Sufficient hauling force with even force distribution along caterpillars

Hauling Rubber easy replace and as spare part delivered for free

Highly Synchronized hauling for stable quality of products

Pneumatic pressure for easy adjustment and product protects

Cutting independent or Hauling & Cutting combined structure available

Swarfless and saw cutting are available up to structure of products

Wide panel product should be stacked for further processing or transportation. The pneumatic stacker takes the panel out of the extrusion line and transport panels to stack station.