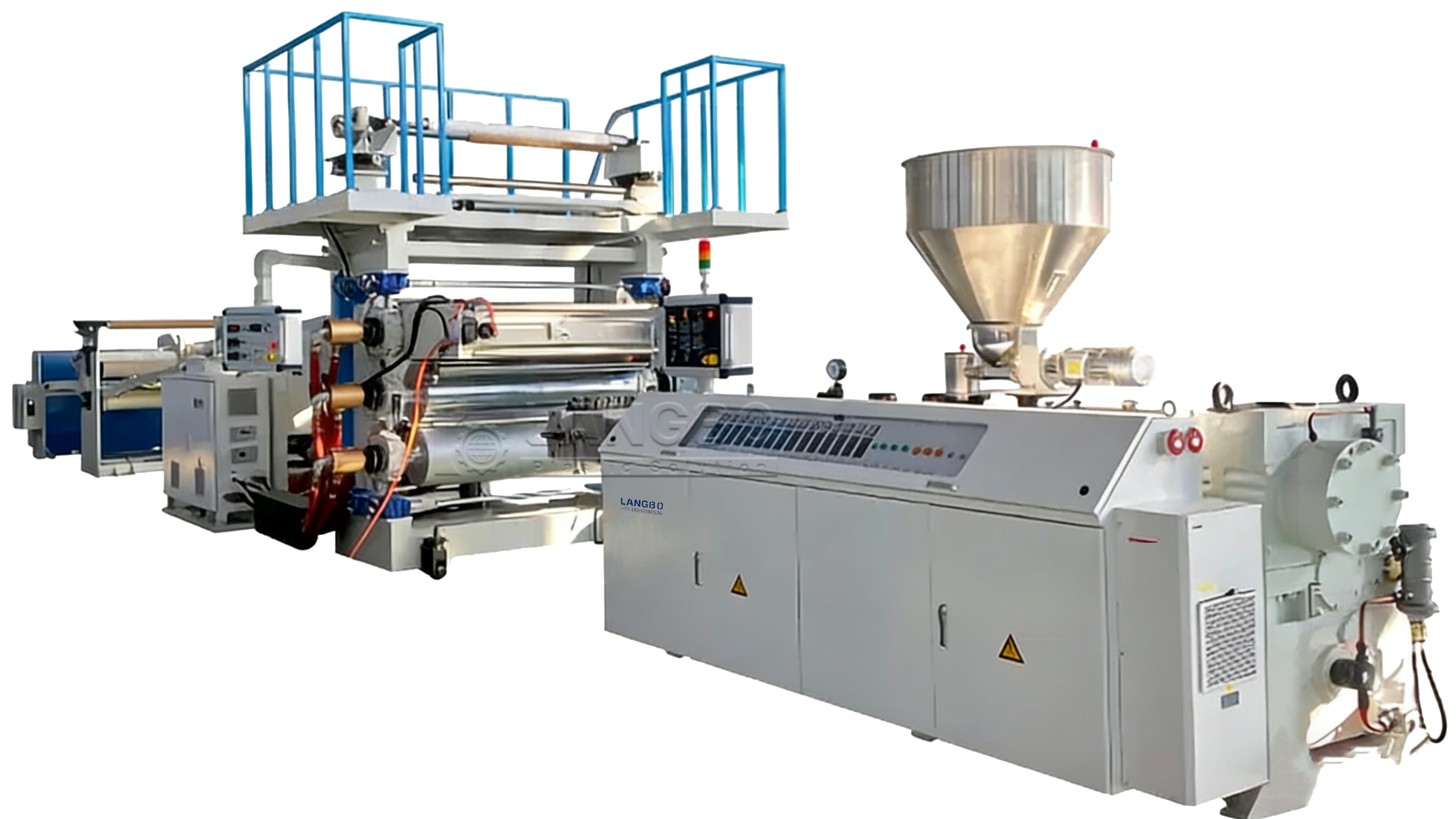

The extrusion line is equipped with a conical twin-screw extruder. The screw structure ensures stable plasticizing and uniform melt flow, supporting consistent sheet thickness and smooth surface quality during continuous production.

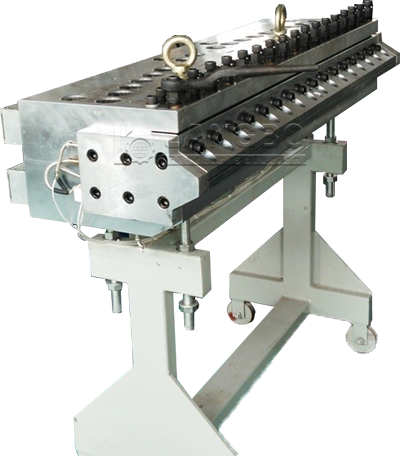

The flat sheet mould is manufactured with precision flow channels to distribute the melt evenly across the sheet width. Adjustable lip settings allow fine control of sheet thickness, ensuring stable dimensions and reducing internal stress during forming.

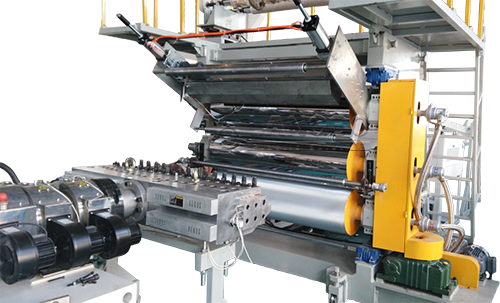

The calender unit consists of multiple chrome-plated rollers arranged for accurate thickness control and surface finishing. The roller temperature and gap can be adjusted according to production requirements, contributing to the marble pattern clarity and surface flatness of the sheet.

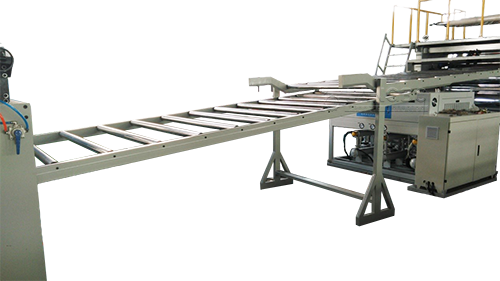

The profile is cooled naturally in ambient conditions, allowing gradual heat release and reducing internal stress. This design helps maintain flatness and dimensional stability without forced cooling interference.

The stacker supports automatic stacking with adjustable height and alignment, reducing manual handling and improving efficiency in downstream packaging operations.