Pre-formed plastic pipes are fed into the machine after the extrusion process. The machine is designed to handle a wide range of pipe diameters and materials, including PVC, PE, and PPR, ensuring smooth and controlled entry into the bending unit.

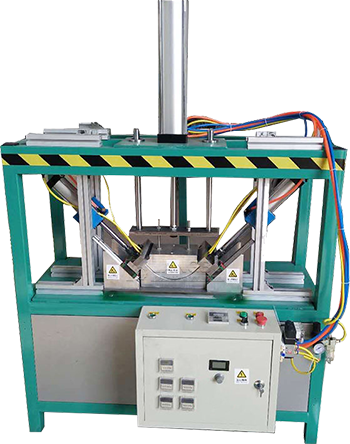

The pipe is heated using electric heating elements to a precise temperature, ensuring uniform heat distribution along the pipe's bending area. This step softens the plastic, making it pliable and ready for bending without causing deformation or damage to the pipe material.

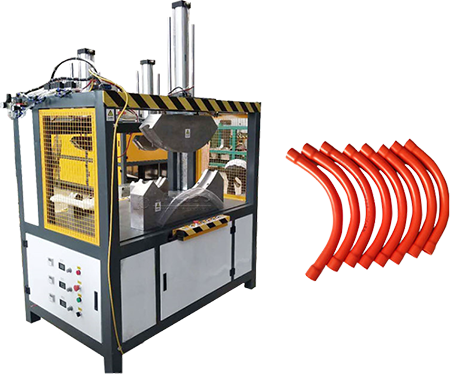

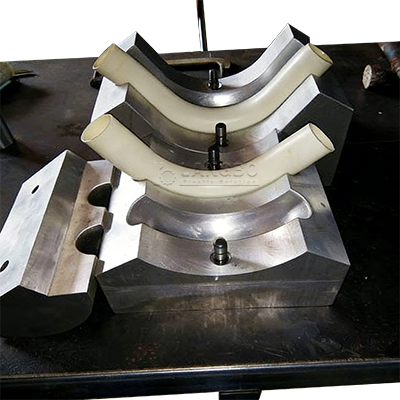

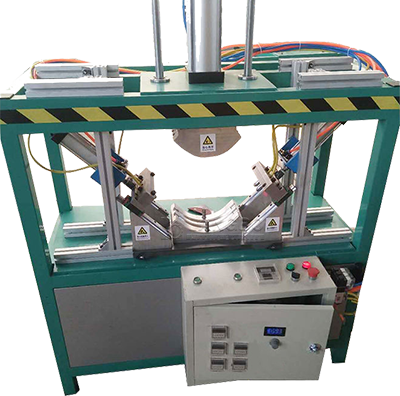

Once heated, the pipe enters the bending unit, where it is bent to the desired angle using controlled pressure. The bending process is fully adjustable, with the ability to set bending angles between 0° and 180°, providing flexibility for various applications.

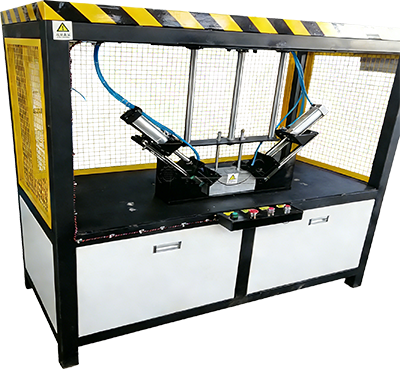

The bending process is controlled by a PLC-based system with a touch screen interface, enabling easy adjustments to bending parameters such as temperature, angle, and cooling time. The system ensures precise, repeatable results for different pipe types and bending specifications.