Poland

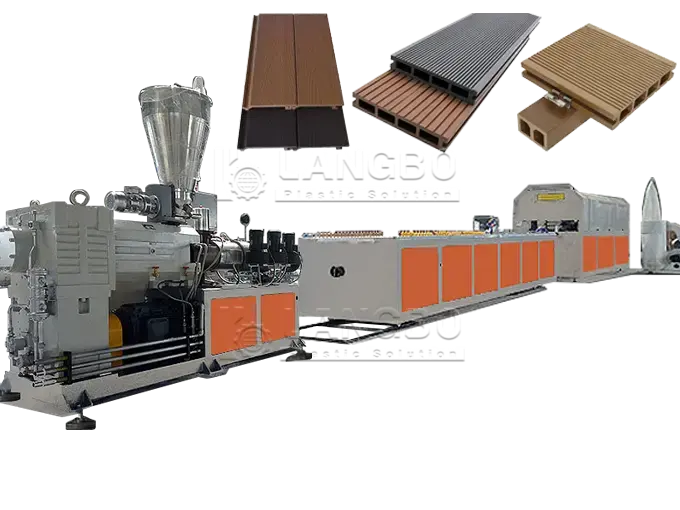

WPC Indoor Panel Extrusion Line

The WPC indoor panel line operates stably with consistent output. The panels have uniform thickness and smooth surface quality, fully meeting our interior decoration requirements.

Highlights

Stable production with uniform thickness and accurate dimensions

Smooth surface quality suitable for lamination or coating

Low noise and clean production, ideal for indoor material manufacturing

Flexible configuration for different panel designs and colors

Tailored Solution

01.

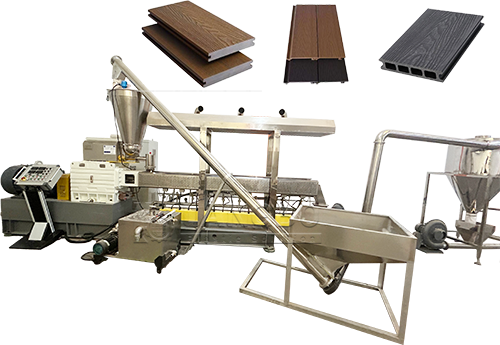

Conical Twin Screw Extruder

Specially designed for WPC material processing, ensuring excellent mixing and plasticization of wood fiber and polymer, stable extrusion pressure, and reliable long-term continuous operation.

02.

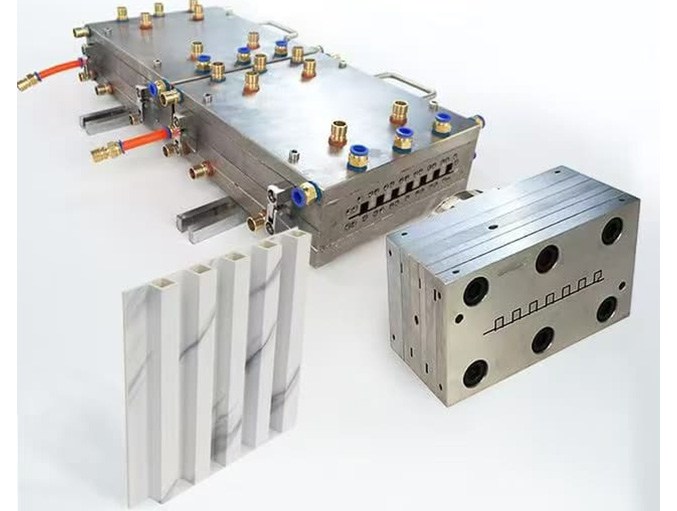

Mold

Precision-manufactured mold tailored to customer panel designs, guaranteeing accurate panel structure, uniform wall thickness, and consistent dimensional stability.

03.

Vacuum Calibrating Table

Equipped with efficient vacuum calibration and water cooling system to ensure precise shaping, excellent panel flatness, and smooth surface finish suitable for indoor applications.

04.

Haul-off and Cutting Combination

Integrated haul-off and cutting unit with synchronized speed control, enabling smooth traction and accurate length cutting while minimizing panel deformation.

05.

Pneumatic Stacker

Automatic pneumatic stacker designed for orderly panel collection and stacking, improving production efficiency and reducing manual handling.